Often, long capillaries are needed for the hook-up, but create quite an additional error, mostly related to the ambient temperature effect on the capillaries. One possible solution could be to make use of compensated capillaries. Before we proceed, first we need to go back a couple of steps. DP Level is always executed with 2 diaphragm seals and capillary lines, to measure the difference in pressure between the 2 nozzle. This can be done with a so-called balanced system (having 2 diaphragm seals with same length of capillary on both sides), or with unbalanced system (having the HP side direct mount and the LP side with capillary). Uneven length of capillaries is never recommendable. For DP Level measurements, Badotherm in general favours a balanced system with equal capillary length on both sides. However we see in the market also often unbalanced systems, with one side direct mount and the other side with capillary. And unbalanced diaphragm seal systems do also have its benefits, especially in ease of mounting, and with higher ranges and stable conditions they can work well.

However, with small spans or fluctuating ambient temperatures these systems may become unstable and unpredictable, to unacceptable levels. One of the best ways of doing so is to reduce the temperature effect on the capillaries. However, this is requiring additional cabling, additional heat racing and increases the (constant) cost of electricity, further increasing the complexity of installation. In general, the TOC increases a lot. Another possible solution is to investigate if electronic (ERS) or digital remote seals (DRS) are possible. But here there are challenges with the accuracy in the span depending to the static pressure on the system. Last, another possibility is a mechanical salutation and that is to neutralize the ambient temperature effect by using compensating capillaries.

With long capillaries, one of the challenges that may occur, is when there is a significant temperature difference exposed to the long capillaries (day & night shift). This causes the filling fluid to contract or expand. Due to the small volume in the diaphragm seal system, this effect is mostly marginal and hardly influencing the measurement. However, with long capillaries this amount of volume increases, and this effect can become significant, or when the spans to be measured are so small, that it helps to eliminate as many effects as are possible.

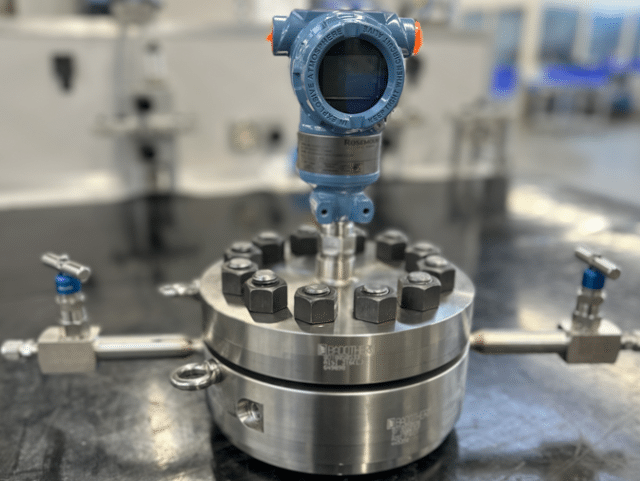

DP measurement used for accurate level measurements

As a manufacturer of pressure and temperature gauges, we are very familiar with compensating effect of a parallel medium. Combining this knowledge and extend towards diaphragm seals technology, resulted in the use of compensation capillaries for some specific applications. It can be used of gauge pressure (see our LGP solution) and for DP level measurements. This knowledge together with the knowledge we built up with the LGP diaphragm seal system for low gauge pressure is combined in the Compensating Capillary Construction.

Compensated capillaries construction is always a combination of one direct mounted seal and one remote mounted seal with a capillary line. The direct mounted seal is having one extra capillary line (that compensates) which is connected to the H-side filling. The compensating capillary is put parallel to the capillary leading from the L-side remote mounted seal.

The extra volume on the H-side has advantages:

* That the static pressure effect which is present with an unbalanced fill.

* The extra fill parallel to the L-side as almost the same thermal expansion due to ambient temperature effects as the temperature effect on the L-side.

* The parallel capillary is compensating the mounting effect when the high and low side nozzle have a vertical distance. This leads to a minimum zero effect after mounting.

As a disadvantage one might say that it is sonly possible with direct mount H-side and that it does not compensate the process temperature difference between high and low side

More information:

Website: Mounting position & installation

Datasheet: Badotherm compensated capillaries

Blog: Badotherm LGP measurements

Brochure: Badotherm Seal Solutions – LGP