Since 2019 we have been developing and testing and several units are supplied in the market since 2020.

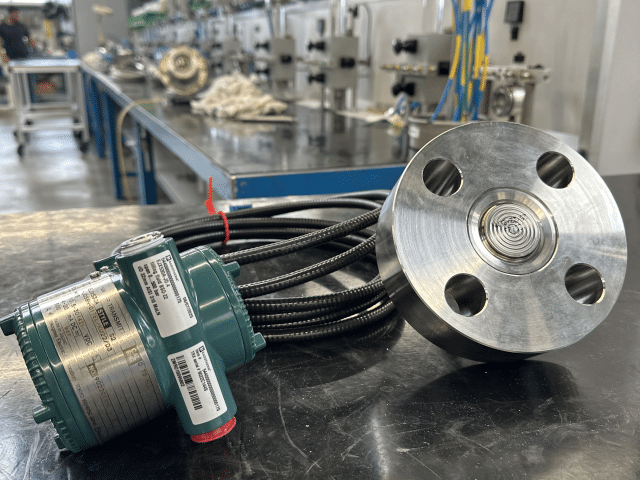

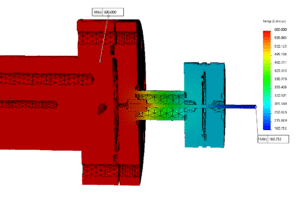

Building on the experience with our proven HTDS design, we have developed a revolutionary construction and filling technique, including a special fill fluid (liquid metal): BSO60. This new design enables us to measure pressure at extreme high temperatures up to 850°C. With these temperatures, we push back another challenge to the industry, being to ensure suitable materials to withstand the pressure temperature ratings. Often, materials that are used in this application are all specifically selected such as Alloy 825 or AISI321, as standard 316SS is no longer suitable.

The updated HTDS 3.0 design can be supplied in all flanged standards, or custom developed process connections. It offers new opportunities in pressure measurements for molten salt heat storage applications or other applications at these extreme elevated temperatures.

More information:

Datasheet: BSO 60 – Extreme High Temperatures

Datasheet: Temperature Compensator