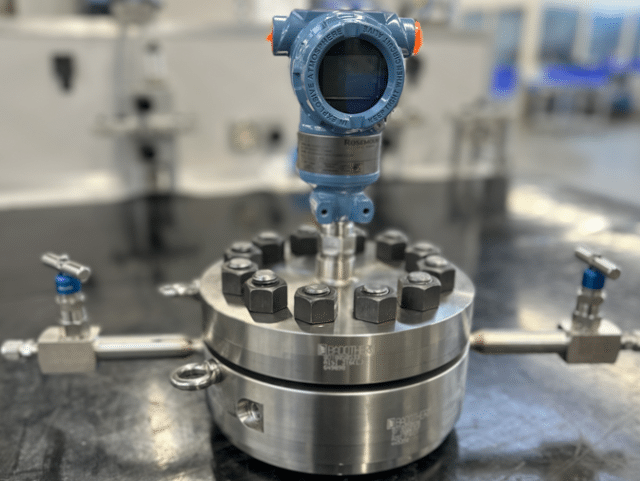

The US-FH seal type

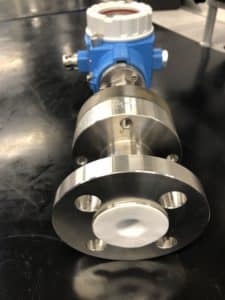

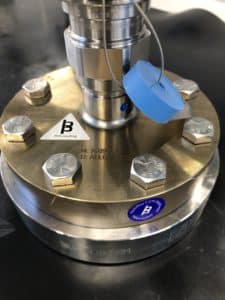

This seal type is the US-FH type, the FH standing for flanged connection in H shape to allow for insulation. The process connection is a DN15 PN10-40. The US-FH series is a two-piece design, that allows for a small process connection, with a lower part that enlarges to a larger diaphragm. And a larger diaphragm allows for better performance and more durable measurements. The complete construction in this case is in full AISI 316(L), with wetted parts in alloy C276 and corrosion resistant PTFE lining.

For additional (corrosion) protection and for non-stick purposes, the alloy C276 diaphragm is covered with a polymer coating on 40 micron thickness, in this case PTFE. All robustly assembled and welded according to stringent procedures by certified welders. And thoroughly tested for performance and pressure tested according to PED guidelines (2014/68/EU).

![]()

More information:

Datasheet: US-FH