So what you do when you have high process temperature, long capillaries and a low measuring span? Normally, a filling fluid suitable for elevated process temperatures, is often viscous and reacts stronger to the ambient temperature effect on the capillary, which you notice in case of a smaller measuring span.

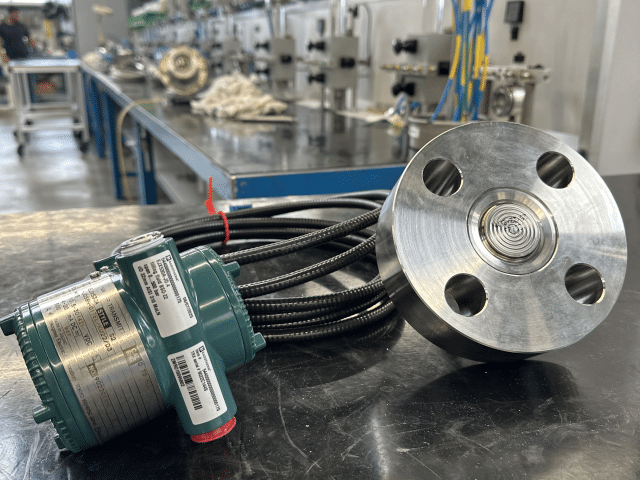

For those situations, Badotherm developed a Temperature Compensator, which is based on a double diaphragm technology. In the first part, the suitable high temperature filling fluid is used. The height is sufficient to cool down the temperature to switch to a secondary fill fluid, that is suitable or optimal to be used in the long capillaries for minimal expansion and thus effect of the ambient temperature effect.

This solution can also be applied in very cold environments, where the response times can increase to a response delay that is unacceptable for the situation. Where fast response times are key to the functioning of a safe operation with high process temperatures the TC can be the solution as well.

Badotherm has been the first to market with this technology since over 25 years. It’s solution increases the thermal range of the complete diaphragm seal system with high process temperature and cold environments.

More information:

Datasheet: PDS_AC_In-Line_Cooler_Temperature_Compensator_Badotherm-1.pdf