Diaphragm seal systems are widely used in all sorts of industries. They can be used to measure and monitor level, pressure and flow. Each of these measurement types have different ways of installation, what we call a different mounting style.

In this series, we explain and introduce the several mounting styles of each situation. Today we will focus on Electronic Differential Pressure Measurement. often also referred to as Emerson ERS System (Electronic Remote Sensor) or Yokogawa DRS system (Digital Remote Sensor). Also other transmitter manufacturers have similar systems.

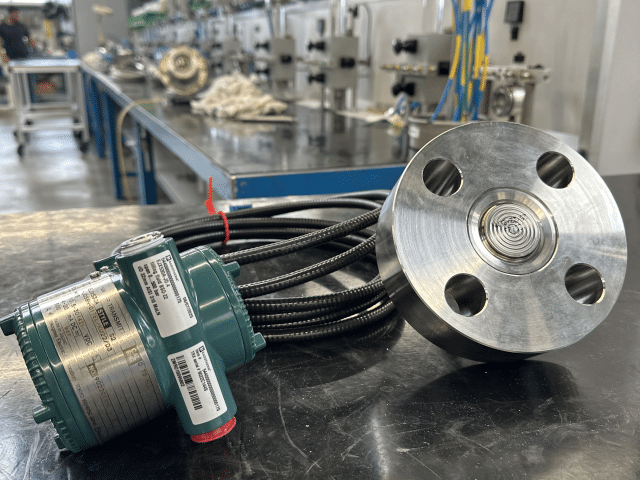

To simplify, this configuration or system works like 2 GP pressure transmitters with direct mounted diaphragm seals, where the two transmitters are connected via an electrical cable. The setup is a Primary – Secondary situation where the differential pressure is calculated by the system and gives this as an output signal. This system is especially suited for large height differences where capillary systems such as tall tanks with nozzles are mounted more than 15 meters apart.

Pro:

* It eliminates the ambient temperature effect of the capillaries

* It eliminates the mounting effect

* Easier handling and installation / mounting

* Diaphragm seal system is more economical (2x GP and no capillary)

* No capillary so no heat tracing and insulation needed over the capillaries to overcome ambient temperature effects

Con:

* Limitations in DP measurement span in relation to static pressure.

* Actual transmitter manufacturer specifications and performance of this system are not so clear. Often only best case situation is described, not worst case (or realistic situation)

* Typically, the direct mounted pressure instrument is not protected against vacuum.

* ERS / DRS might be a more expensive system overall

* Additional requirements for the cable.

* TPE calculation is more complex, since it has to take into account 2 separate gauge pressure measurements, and thus 2 TPE’s.

If ERS or DRS system is the ideal solution for your situation, depends on several factors. Not taking all the diaphragm seal systems into account correctly, may result in this case that the measurement could fail. Hence proper engineering and checking of this situation is ideal for your situation is essential.

With the use of our BaseCal tool, we can easily check this for you. Contact us if you need any help.

More information:

Measurement & Installation styles – Badotherm