Hub Connector

In the last decade, we have seen the number of diaphragm seals systems with pressure ratings of cl. 1500 and cl. 2500 RF and RJF going up significantly. Next to the ASME B16.5 flanged connections, we also see the high pressure standard like the API 10423 – Type 6BX more and more. These flanges with high pressure ratings are large and thick flanges containing a lot of material and thus are mostly very heavy in weight, especially for the 2″ and 3″ flange size. Still, the flanged connections remain THE standard in the heavy and demanding petro-chemical industry and the total installations are mostly aligned with these dimension. Also, there is the most experience in installation and working with these flanged connections and related selection and usage of gaskets and bolting. And in many applications, the weight of the flange of the pressure measurement might not always be that important. However, in some applications, the weight of a flange can be of large importance. Can you imagine a level measurement with 10 meter of capillaries on both sides with a 3” cl 2500 RJF flanges to be mounted on the nozzles with a center to center distance of 12 meters, with each flange weighing easily over 25kg. With a hub connector, this weight can be considerably reduced. This can result is easier installation, lighter construction, less stress at the nozzle, and possible in a more efficient (cheaper) construction without any extra supports. For this reason, the hub seal construction are used more and more.

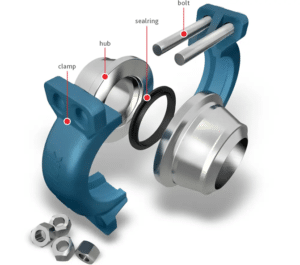

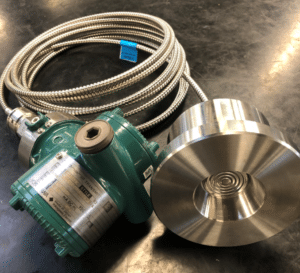

Hub connectors or hub and clamp joints are an alternate method of joining pipes as compared to traditional ASME B16.5 pipe flanged joints. Pipes and equipment can easily be joined using clamp and hub connectors as this metal-to-metal sealed connector is highly reliable and easy to assemble. The clamp joint has the following configuration: 2 clamps, 2 hubs, 1 seal ring, 4 studs and 8 nuts. The seal ring is a zero leakage, reusable, metal-to-metal gasket interfaced with the hub sealing surface to ensure high integrity and a reliable seal. The joint configuration ensures that the seal ring is elastically loaded during assembly to offer a self-energized seal during operation.

The drawback of these hub seal connections are their patented or classified designs. Even though several manufacturers have sprung out of the same source (origin), they all have different interpretations and have gone their own way. Since they keep their designs and dimensions classified. This makes the gasketed design not standard and fixed to one manufacturer. Even though some manufacturers claim interchangeability, they tend not to confirm this. The most common hub manufacturers are Grayloc® (Oceaneering), Vector Techlok® (Freudenberg), Galperti® and Destec®. There is a large variety in size and dimensions with each of the manufacturers, that can make it quite a puzzle.

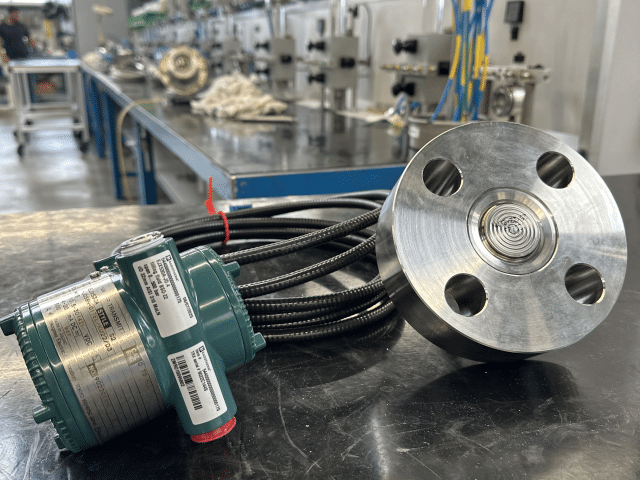

It is important to note that Badotherm does not manufacture the hub connectors itself. These are always free issued to us by the customer and are always manufactured by the original manufacturer. Badotherm also only requires the hub connector, and don’t require counter (process)hub, nor the gaskets, bolts and clamps, which are mostly all ordered together. but it is important for us to know what hub we will be receiving.

Experience in manufacturing hub connector diaphragm seal systems

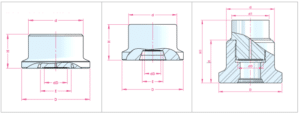

Over the last 15 years, we have been supplying more and more hub connector diaphragm seal applications and we have built up a vast experience in the engineering, the manufacturing and the testing of these diaphragm seals systems. With each manufacturer, type and size, the space allowed for the diaphragm might be different, so during engineering, the first thing we do is determine the largest diaphragm possible and needed for the application. Our aim is always to have the diaphragm as large as possible, to allow for the best possible diaphragm. However, we are also bound by the type used.

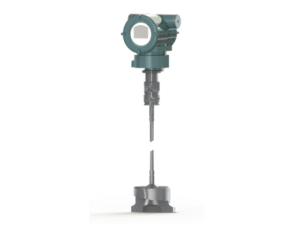

There are basically 3 types that can be manufactured: a front face design, a recessed design or a weld-in design. We prefer to have hub connectors based on a front face design, as this allows for the largest diaphragm possible.

Depending on type, size and rating this construction may be more difficult to manufacture. The depth of the recessed area makes machining more difficult. Also, it may result in smaller diaphragm diameter, which could impact the overall performance of the instrument. Also, since used with high static pressure, the compression of the system fill volume need to be taken into account. This fill fluid compression of the high static pressure, is further impacted and counter balanced by high process temperatures, but in the end depend on the total fill fluid volume in the complete system and the related length of capillaries and the ambient temperature that the system is exposed to. Sometimes, the pressure transmission might be sufficient, but the flexibility of small diaphragm can be stretched resulting in overall reduced lifetime and reduced robustness. Especially in combination with longer capillaries, elevated process temperature or changing and more stretching ambient conditions, it is important to take all these factors into account to make the based possible system. And in combination with DP (level) measurement, the diaphragm diameter can be important in case smaller spans are required to be measured.

Due to our large availability of diaphragm materials, we have executed these hub connectors in many materials amongst which AISI 316(L), AISI347 , Super duplex F53 and F55 and alloy400 and alloy 625.

Some Benefits of Using Hub & Clamp Connectors

As compared to the conventional flange joints, the clamp and hub connection joint provides the following advantages:

- Simple Connection requiring only four bolts.

- Lightweight & Smaller in size; Compact Design: Hub and clamp connectors usually have around 80% less weight, 10% less outside diameter, and 50% less overall length than the standard ASME B16.5 flanges. Hence, they use significantly less space.

- Reduce Downtime as can be assembled or dismantled quickly with fewer bolts.

- Economical Solution: A hub and clamp connector provide an economical solution for piping joints by reducing the total cost of installation.

- Leak-Free: Clamp and hub connectors can withstand higher temperature and load variations and ensures leak-free operation when installed correctly.

- 360° orientation around the pipe is possible.

- Lower Bolt torque

More information:

Datasheet: Badotherm BHS Hub Connector

External website: BlueSky Bluelock Clamp Connector: Freudenberg (ffltech.com)

External website: Grayloc® Clamp Connectors | Oceaneering

External website: G-LOK® CLAMP CONNECTORS – Galperti Group

External website: G-Range Clamp Connectors – Destec Engineering Ltd