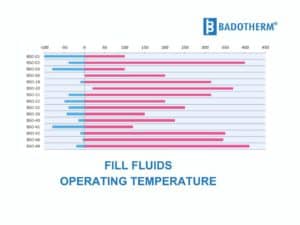

Next to the type of fill fluid (inert, silicone or sanitary) which we touched upon in our last post; the operating temperature of the fill fluid is the second important factor for selection.

The application temperature should remain between the fill fluid limits to guarantee proper functioning of the application. All fill fluids expand or contract with changes in temperature and this is referred to as the diaphragm seal temperature effect.

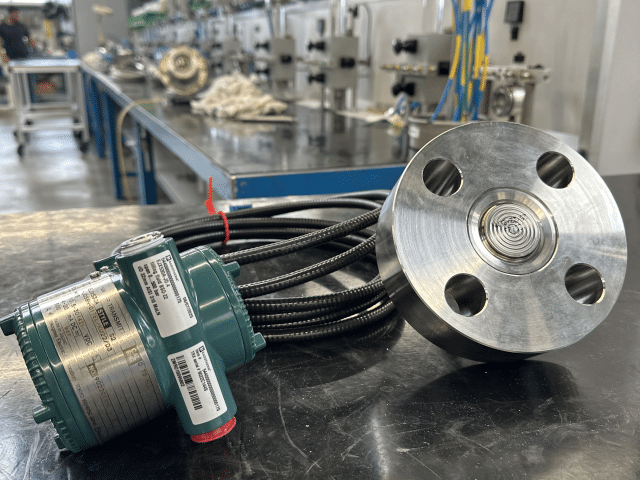

Density, viscosity and capillary length and diameter are parameters that determine the response time of the diaphragm seal system.

The vapour pressure is one of the most important characteristics for fill fluids of diaphragm seals. As diaphragm seals are often used under vacuum conditions, it is of vital importance to select the appropriate fill fluid that withstands the vacuum and temperature, Badotherm can handle 230°C @ 1 mbara.

More information:

datasheet: Badotherm_seal_filling_fluid_overview.pdf

Also here BaseCal can help to make the proper selection.