As a manufacturer of pressure and temperature gauges, we are very familiar with the compensating effect of a parallel medium. Combining this knowledge and extend towards diaphragm seals technology, resulted in the use of compensation capillaries for some specific applications. With this knowledge we build the LGP diaphragm seal system for low gauge pressure and developed to compensating capillary solution for DP measurements.

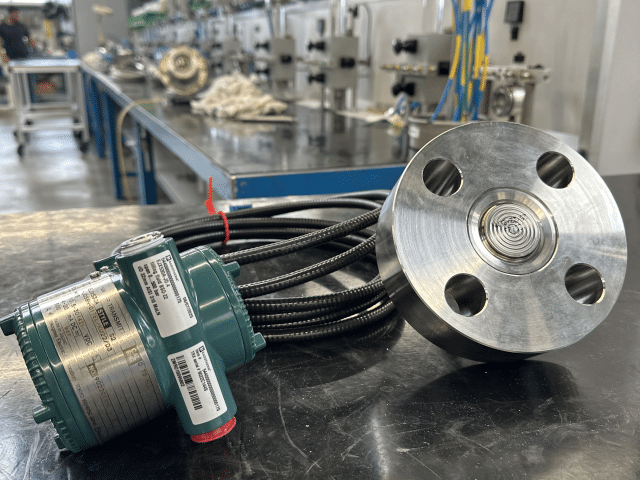

For measuring very low spans in gauge pressure measurement we take things even to the next level. Whereas for the level measurement, the compensating capillary mainly is used to minimize the ambient temperature effect. For gauge pressure, with a double diaphragm technology, we compensate for both process AND ambient temperature effect to bring this to an absolute a minimum. For this gauge pressure measurement, one requires a DP pressure transmitter. Here one capillary line of the diaphragm seal system is connected to the HP side of the transmitter and transmits the process pressure and temperature. The other (compensating) capillary line is connected to the low-pressure side of the transmitter and is exposed to the same process temperature and same ambient temperature effect. And thus, the measurement is compensated for the process temperature effect. Result: the process temperature effect and the ambient temperature effect are compensated (neutralized) and thus the only effect that the instrument measures (senses) is the process pressure.

For the GP measurement, capillaries are always needed, but need to be kept as short as possible (often limited to 1 or 2 meter for best performance). This way, with gauge pressure measurement, and the double diaphragm technology compensating for both process as ambient temperature effects, we can go as low as 5 mbar span with Diaphragm Seals.

read more:

Website: LGP – Badotherm

Blog: Compensated Capillaries for DP Level measurements with diaphragm seals