This surface alloy was designed with high performance in mind for aggressive applications that require corrosive protection or inertness. Due to the process of applying the surface treatment, it is not possible to apply this to the diaphragm itself, however for other components such as flush rings, lower parts, thermowells and manifolds this is an interesting solution.

For several customers Badotherm recently supplied components with Tantaline® surface treatment:

• For the Qarn Alam project, the required thermowells had to be compatible to 36% HCL concentration. The materials of construction should therefore be tantalum or zirconium. Tantaline® treatment of the thermowells was chosen as the most effective solution.

• For a leading Dutch specialty chemical company we supplied diaphragm seal type USF with a tantalum diaphragm and a lower part with a Tantaline® treatment. In this case, it replaces a PTFE lining.

• For the Laggan Tormore project, we supplied seal type BRF with tantalum diaphragm and a flushing ring with Tantaline® treatment, including the blind plugs. One of the benefits of Tantaline® treatment is that is it suitable for threaded connections (e.g. the plugs).

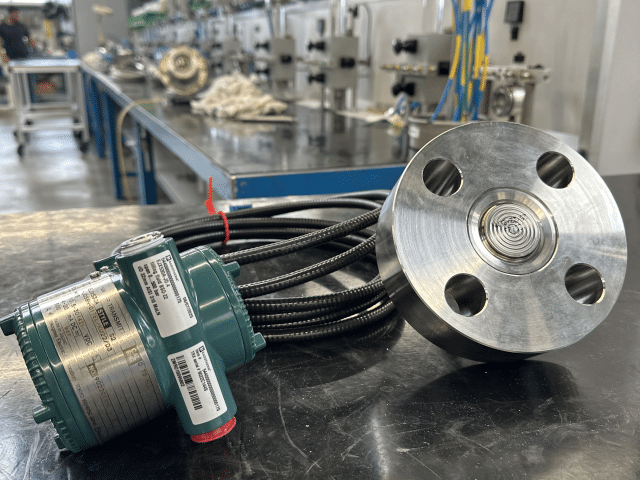

• In the above pictures the tantalum is also a very beautiful solution as it is the preferred material for corrosion resistance. In this case executed with USLF and Rosemount transmitter. The diaphragm is of course also of tantalum, ensuring 100% wetted parts of tantalum. Alternative solutions you might find are with Alloy c276 lower part and tantalum diaphragm or you will find a 316SS lower part with PTFE lining. Up to the customer as per what they prefer.

Want to know more about Tantaline®? Click here