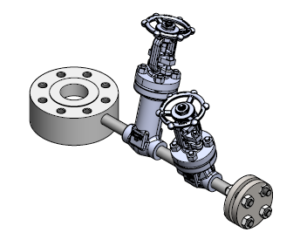

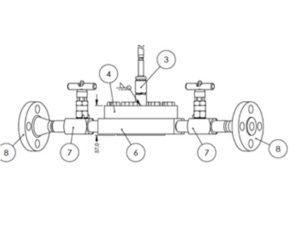

The flushing flange or ring is often used for flushing solutions combined with diaphragm seals. The flushing flange or ring is clamped between the process nozzle and diaphragm seal. The flushing ring should be seen as a diaphragm seal accessory that is carefully designed to optimize the use of the diaphragm seal in your process conditions, or to ease the installation and protect it against damaging during installation. For this reason, Badotherm supplies perfect matching flush constructions.

User case: Special lower part construction

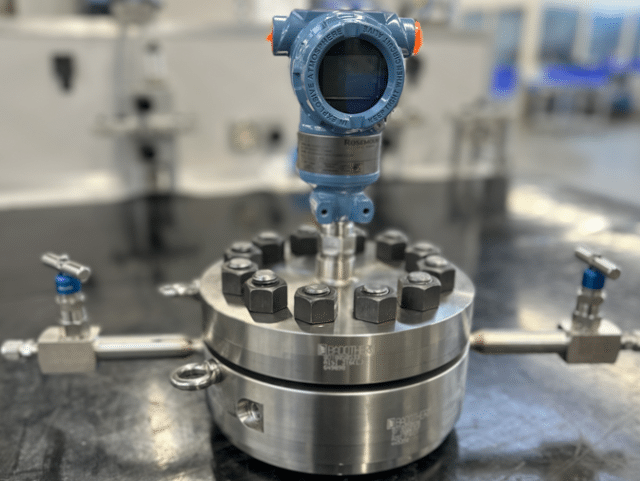

Since many years Badotherm supplies its diaphragm seals to a leading petro-chemical company in South Africa. For one of its most severe processes in the alkylation production, it is using Badotherm diaphragm seals with a special lower part construction in the diaphragm seals.

In this construction, Badotherm uses its USL diaphragm seal type with the lower part made in Alloy400. In the lower part, there is a special flush construction built, all from alloy400 materials. There are welded flush valves type BDTV910 in ally400 with special welded ends, further extended with welding neck flanges in alloy400. The welds are of a different kind. The valve is butwelded to the flange, and there is a full penetration weld between the valve and the welding neck flange. Prior to manufacturing, a welding dossier was prepared for approval containing a full set of WPQ / PQR, as well as a full NDE test plan, including dye penetrant testing and X-ray testing of the welds.

For the instrument, a Honeywell transmitter STD820 was chosen, assembled with the Badotherm USL diaphragm seal by means of a full welded construction. Further, for increased chemical resistance and to prevent hydrogen permeation, there is a 40-micron thick layer of 24 CRT gold applied. This application, specially made for these hard circumstances, has a proven track record for the end user.

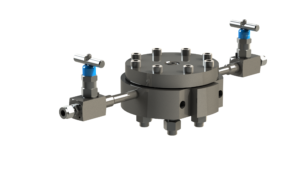

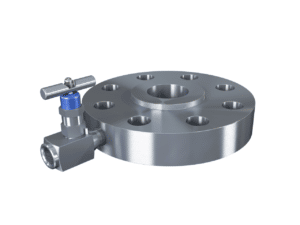

Fitting or welding the flush accessories valves on the flush ring and reducer flanges

Flushing (drip) rings, flush flanges or reducer flanges; these are all accessories to the diaphragm seal assemblies as manufactured by Badotherm. Often these rings are requested in combination with flush valves or with welding neck flanges, or a combination of these accessories. For the instrument needle valve, or flush valves, Badotherm has either model type BDTV910 or BDTV911,. The BDTV911 is specially designed for the flush ring, which has an extended connection on the process side to ensure sufficient distance with regards to the diaphragm seal flange. the instrument valves can be fitted to the flush rings, but it is also possible to have them socket-welded (SW) or butt-welded (BW) to the body material. The welds are often requested in combination with stringent qualifications. As such Badotherm supplies these, upon selection, with complete WPS, WPQ and PQR. And with a full NDE test plan of the construction, matching the specific requirements of the customer.

Additional reading: