Why LoRaWAN?

LoRa® (standing for Long Range) is a LPWAN technology, characterized by a long range associated to a low power consumption. It is a technology that can be parametrized to change its range and data rate, influencing its power consumption. It is usually provided with its integrated MAC layer called LoRaWAN, offering IoT-oriented devices management. It is relatively easy to set up thanks to the public network coverage provided by the TTN.

The LoRaWAN open specification is a low power, wide area networking (LPWAN) protocol based on LoRa Technology. It is developed by the LoRa Alliance, an open association working on LoRa devices and networks (see their site for more detailed protocol reference). The LoRaWAN Protocol is used in closed factory environments. Used as data network for data gathering of assets such as location, pressure, temperature, vibration, setpoint, etc. It provides an environment that continuously allows to monitor equipment conditions with multiple types of sensors. LoRaWAN has excellent sensitivity reception, good radio interference resistance, and offers a communication distance of 10 km or more in an ideal communication environment.

What we see as the main benefits for wireless (LoRaWAN) sensors are the following

- reduced man-hours for collecting data

- quantification of measurement data that previously was only remotely available

- automated data acquisition and storage systems

- increased possibilities for Asset Performance Management (APM), Predictive and Condition Based Maintenance (CBM).

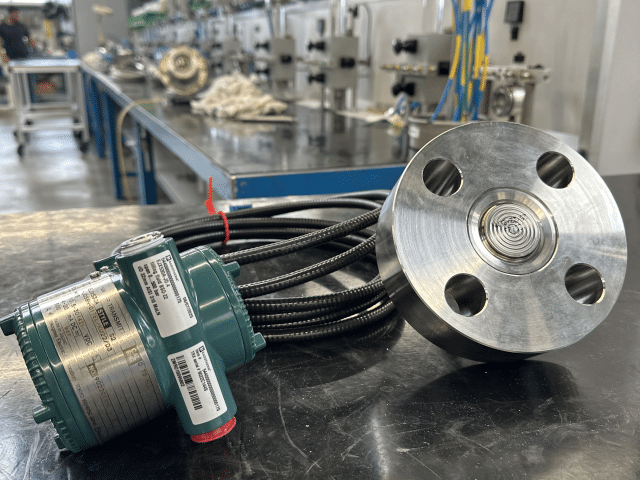

Badotherm, being a pressure specialist, focuses on the developments of the wireless Pressure Sensor. Badotherm have made their traditional pressure gauge suitable with a TWTG LoRaWAN Neon sensor. This product acts as a battery-powered wireless pressure sensor, and it is suitable for Industrial IoT (IIoT) applications. The large advantage is that this has the same specifications as a pressure gauge and can be easily replaced for current applications. With the main benefit that you can still read the pressure remotely. Another development is the Sushi sensor for pressure and vibration manufactured by Yokogawa.

Just like pressure transmitter, Badotherm can mount any diaphragm seal configuration to the pressure gauge or the Yokogawa Sushi Sensor. The impact for Badotherm is in the communication and testing of the instrument with the LoRaWAN protocol. This has a slightly different approach then standard pressure transmitters. As the LoRaWAN instrument is based on a capture of the pressure of a certain moment, the accuracy of the reading is not as accurate as real time (wired) pressure transmitters. The reading can only be done manually with an Android-based smartphone with NFC (Near Field Communication) interface that you manually refresh. The time delay is seconds. This means the verification of the system is a comparison to the input pressure and the reading on the mobile phone. These values are manually entered in our calibration system. For communication purposes, we need to have the wireless communication module XS110A along with the XS530. Only with the set, we can communicate with the sensor. Otherwise it will be send without verification and only a pressure test on mechanical integrity.

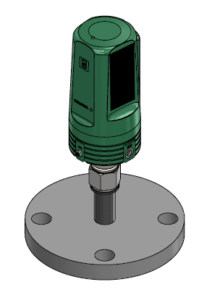

We have some nice examples of how we applied the Yokogawa Sushi Sensor onto our diaphragm seals.

Case study 1:

One of the largest petrochemical companies in the world is heavily investing in LoRaWAN. In this case a Yokogawa LoRaWAN Sushi Pressure Sensor with remote diaphragm seals BF and capillary for high temperature application up to 420°C. It replaces a standard pressure gauge with seal which is currently being monitored to each operator visual check-up round. Now the data will be automatically send to the rotating engineer and the measurement is digitalized in an easy way without any wires and cables.

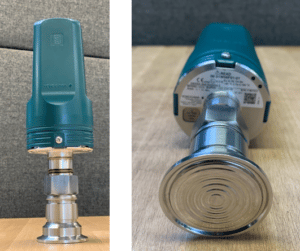

Case study 2:

For a customer in the pharmaceutical industry, who wanted to switch from ISA100 to LoRaWAN protocol. Here the new Sushi Pressure sensor series “pressure measurement module” XS530, is used with a diaphragm seal. The diaphragm seal is a sanitary tri-clamp connection (type SAT) with electropolished treatment for reduced roughness (Ra ≤ 0.38 μm). In this specific case, which was a mobile vessel in which they wanted to control a certain minimum pressure, whilst moving the vessel through different locations in a big building. Hence no electrical wiring desired so the wireless sensor was an ideal solution.

please contact us in case you have any specific questions regarding our LoRaWAN pressure gauges or the mounting of diaphragm seals to the Sushi Sensor. For some interesting references and additional reading, please find few links below.

Blog: Press Release: TWTG and Badotherm agree Partnership for LoRaWAN Pressure Sensor Development

External website: Draadloze druk sensor | Yokogawa Nederland

External website: LoRa Alliance® (lora-alliance.org)

External website: Digitising Industrial Sites: LoRaWAN & WirelessHART – Whitepapers – TWTG