Flushing Rings

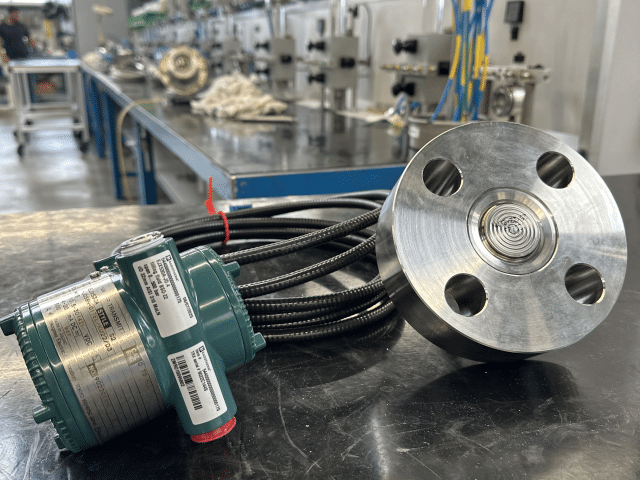

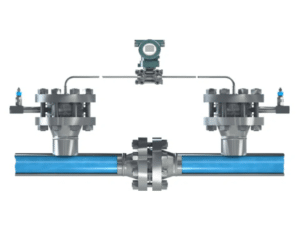

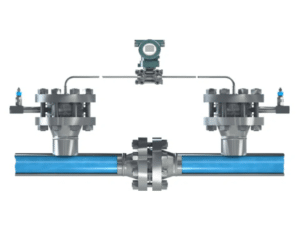

There are several names for flushing rings, mainly referred to by their function, but the base design is all similar. All are being sandwiched between a diaphragm seal and the process nozzle. The most common name that is used, is “flushing ring”, which emphasizes its flushing capabilities. This allow users to “flush” out process medium built-up on the process diaphragm. Commonly, the flushing constructions have one or two threaded holes in the side of the construction called ‘flushing connections’ or ‘flush ports’. These flush ports are standard (blind) plugged or directly connected to a draining system. The main advantage is that you can flush the system without disconnecting the remote seal from the process flange. The flush ring pressure chamber that can be vented or drained. This construction can be filled with cleaning detergent and flush to clean the diaphragm.

Drip Rings

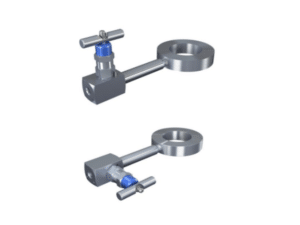

The name “drip ring” reflects its primary function of dripping, draining, and/ or venting. It refers to the process medium to drip out. These constructions are commonly used in applications where clogging or venting may occur, and they typically have one opening and a vent plug or valve.

Calibration Rings

The moniker “calibration ring” highlights its ability to allow for calibration without removing the instrument from the process. By being sandwiched between the diaphragm seal and a process flange, the flushing connections on the side of the ring provide access to a known pressure source, enabling users to calibrate the unit against that known pressure. Additionally, the flush ports can be used to calibrate the instrument by pressurizing the cavity and calibrating the instrument against the pressure.

Heat Dissipaters

It is unusual to order a flushing construction without a flushing connection, but sometimes it is or can be used as a spacer or a heat dissipater. The flush ring extends the height of the construction and could allow for some cooling, depending on the ambient conditions. if there are elevated temperatures over time, it will loose its cooling effect.

Size, pressure rating and dimensions

Flush rings typically follow the gasket dimensions as per the flange standard, e.g. ASME B16.5 or EN 1092-1. For ASME for example, for the standard RF facing, the dimension per size is the same regardless of the pressure class. a 2″ flush ring can be used for class 150 up to 2500 and has same dimension. However, for other facings, this is not applicable and each size and rating is unique, e.g. a 2″ cl 900 RJF.

Conclusion

Normally, several of the above functions can be combined, so there is no single function. Mostly, first the liquid residue is drained, then excess residue is flushed out with a cleaning detergent, after which the instrument can be calibrated. In case there’s a malfunction, the instrument can be dismantled and replaced or the instrument can be returned for an inspection and refurbishment. In conclusion, flush constructions are key components in pressure measurement applications with a variety of functions such as dripping, draining, venting, calibrating, and cleaning. We hope that the insights provided in this post give you a comprehensive understanding of the different applications of flush construction, allowing you to make informed decisions when it comes to designing your ultimate pressure measurement solution.

For the difference between flushing rings and flushing flanges, we refer to out other blog regarding this topic. Blog – The difference between flush rings and flush flanges

More information:

Datasheet: Flush rings

Datasheet: Flush flanges

Datasheet: Instrument needle valves

Blog: Special flush constructions with welded valves or welding neck flange