Introduction

Flow measurement by primary flow elements and differential pressure sensor (ΔP) is one of the oldest and most widespread technologies in the industrial world. A primary flow measuring elements can be either an orifice plat, a venturi tube, a pitot tube or others. Traditional dP transmitters or a multivariable that compensates the flow rate with the pressure and temperature to obtain a mass flow rate can be combined with such a primary flow element.

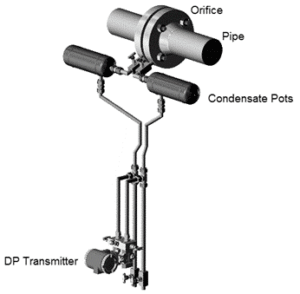

Traditional hook-up with impulse line

As the dP pressure transmitters can withstand only a maximum process temperature of 120°C, the instrument needs to be protected against this elevated temperature. In the past this was done by means of shut-off valve, a condensate pot, a 3- or 5-way manifold and all connected by means of impulse lines as shown in the example of figure 1. This to cool down the process temperature sufficiently.

FIgure 1: original hook-up with impulse lines.

However, the original hook-up gave the customer several challenges. First of all, the impulse line are connected by means of (double ferrule) fittings, the latter are prone to have leakage over time. Also, the system is prone to freezing and subject to large ambient temperature effects. The hook-up with its fixed structure was considered not flexible and and this construction requires regular maintenance and control. Therefore, the customer was looking for a alternative and better solution.

Direct mount with PTH diaphragm seal

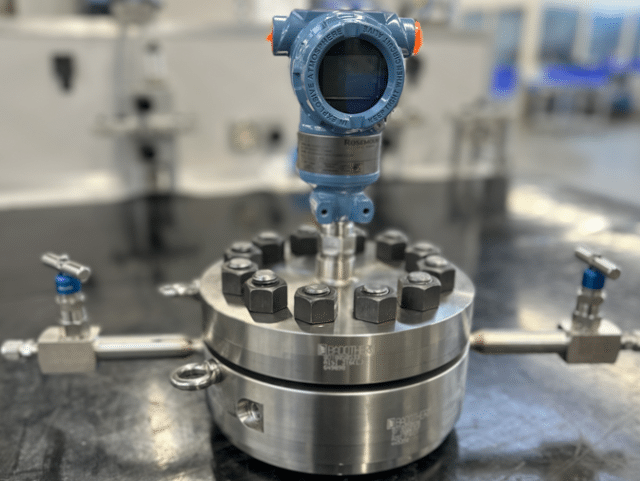

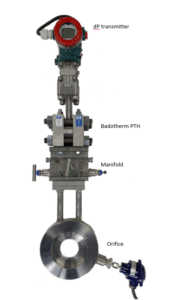

Taken above challenges into consideration, it is clear that this type of traditional mounting with impulse lines is high maintenance and thus expensive, also after installation. Therefore, Yokogawa France developed a smart and robust solution using a dP (or multivariable) transmitter equipped with the Badotherm PTH diaphragm, that is able to withstand a process temperatures up to 420°C and still can be mounted direct on the 3- or 5-way manifold, without any tubing. See figure 2:

FIgure 2: Improved hook-up with direct mount PTH diaphragm seal on manifold block, straight to the process via the orifice plate.

As in this type of direct mounting, no impulse lines are involved, the risk of leakages is eliminated, with all benefits for the maintenance requirements. This also results in a very reliable dP flow measurement, certainly over a longer period of time.

With the Badotherm PTH, the cost of ownership is thus considerably lower than with the traditional mounting.

More information:

Datasheet: PTH Direct Mounted to Rosemount

Datasheet: PTH Direct Mounted to Yokogawa

Brochure: PTH Diaphragm Seal Solutions

Blog: PTH diaphragm seal – high temperature direct manifold mount