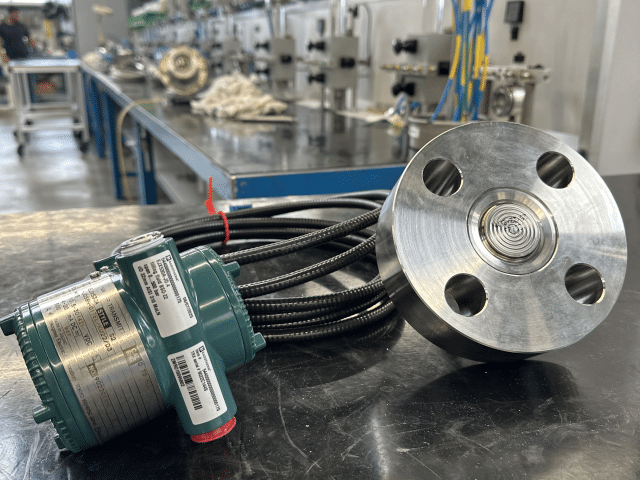

For one of our appreciated customers, we were requested to manufacture a diaphragm seal system with an Emerson 2051CD 3A differential pressure transmitter and 10 meter of capillary, filled with high temperature filling fluid BSO-42. The diaphragm seal construction was executed with a full welded construction and the diaphragm seal design based on Badotherm FSO-EXT-UREA type, with an extension length of 300mm. It was fully executed in wetted parts material Titanium Gr.2 and diaphragm Titanium Gr.1.

The FSO-EXT-UREA diaphragm seal is based the on original CASALE design standard (standard Z00000L-G-MTP-11) and contains a 4″ NPSM lens seat with a cover flange in material ASTM A350 LF2. Instead of lifting handles, the coverflange is equipped with a lifting eye hole, to facilitate easy transportation towards the site, where a lifting lug can be inserted.

More information:

Datasheet: FSO-EXT (UREA)

Blog: Full welded construction: increasing reliability in vacuum conditions

Blog: UREA production