Being the actual measurement instrument, the transmitter specifications are an important to manufacture durable, robust, high quality and high performing diaphragm seal systems. A check on the suitability of the pressure transmitter is important to avoid undesired delays and inefficiencies. And since the diaphragm seal assembly is always done at the end of the lead time, any delay at this moment is inconvenient. And if the transmitter is not suitable, a re-delivery of a single pressure transmitter could result in a delay of several weeks and could delay also the complete order. Mostly, in case of receipt of pressure transmitters with different specifications than specified in the order, it requires small modifications to the production order and require different nipples than planned for. Which may also delay the delivery and or may bring additional cost.

Therefore, upon receipt of order for diaphragm seal assembly, we also ask a confirmation of the pressure transmitter details. We do this to ensure suitability of the pressure transmitter for the application. This to ensure that the right transmitter is ordered to the factory and supplied correctly to use, thus ensuring last minute delays. But also to ensure that the right components are manufactured and included to ensure most efficient assembly and optimum system design. This helps to keep our delivery commitments of our customer to their customers.

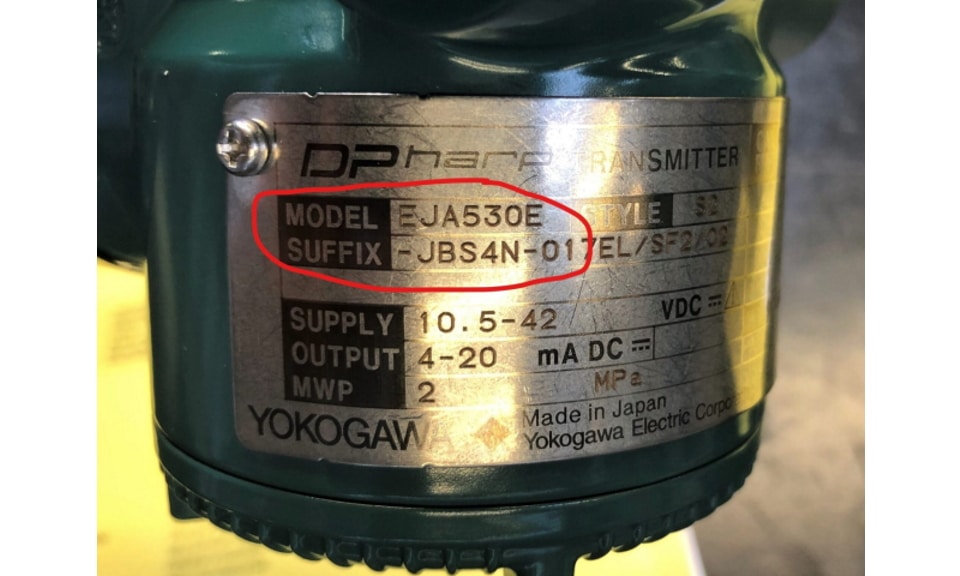

When receiving the order, we always require confirmation of the following information.

- transmitter type and model

- cell code

- transmitter process connection

- communication protocol

All this information is typically mentioned in the complete transmitter ordering code. For your convenience, we can easily get the required information from these transmitter codifications, regardless of the brand. Hence you can also confirm us the complete pressure transmitter ordering code, and we take care of the rest.

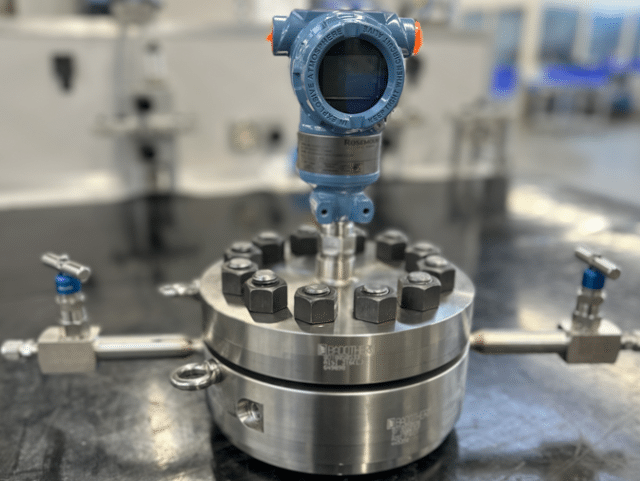

Transmitter type and model

Transmitter type and model are important to know to verify the correct transmitters are supplied for the application (GP or DP) and this provides information for the transmitter specifications and the diaphragm seals construction.

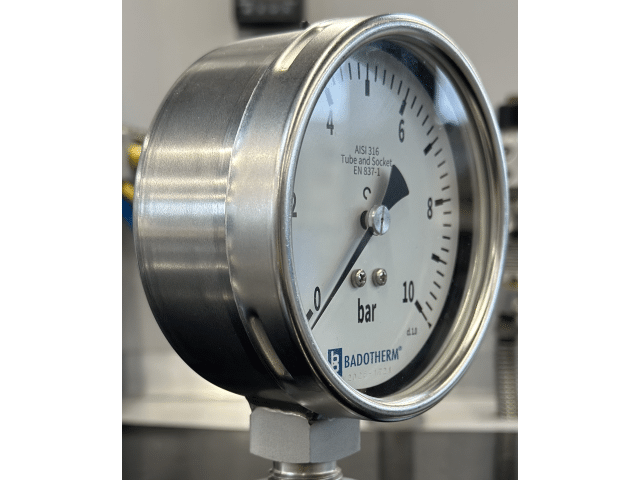

Process connection

The principle of diaphragm seal measuring technology is based on the transmitting the pressure by means of a hydraulic system. The transmitting fluid cause a temperature effect. Hence it is essential to reduce the amount of filling fluid in the system. Badotherm designs and manufacturers all components in house and takes the best suitable adapters, nipples and low volume covers possible. A different process connection means a different component in the bill of material. Therefore it is essential to know the process connection at time of order, so the right component is selected based on the transmitter connection supplied, so we don’t have to change the production order and related bill of material, because a different transmitter connection is supplied.

- Process cover flange: low volume flange supplied (Yokogawa), or Badotherm.

- Threaded ½” NPT-female, Badotherm low volume welding nipple.

- Weld in nipple

- When a BSP male is supplied, this means a different nipple but also it is impossible to reduce the volume in the nipple

Output signal / Communication Protocol

We also like to know the Output signal / Communication Protocol of the pressure transmitter. This is important information for our planning in production during final testing. Some protocols just communicate a little faster or easier than other protocols. This information allows our planning to allocate the resources in a correct manner. Again, to ensure that our and your orders arrive timely to our customers.

Capsule or Cell code

We always ask for the cell code as this allows us to cross check the selected capsule (measuring range) and required span:

- To be able to check if the requested span fits into the selected capsule range.

- To be able to check if the requested span is possible with the diaphragm seal configuration

Some cell codes or capsule are not possible due the diaphragm seal configuration, which can be dependent on many variables, such as diaphragm diameter, flange rating, capillary length and diameter, and many more. In some occasions, an incorrect cell code is selected and provided to Badotherm, which cannot measure the requested span. Knowing this in advance, avoids significant delay in the supply chain, as otherwise we only find out that when the transmitter is at Badotherm. By that time, we have all components ready for assembly, only with the incorrect transmitter due to the incorrect cell code.

If you have any further questions, please do not hesitate to ask your Badotherm sales representative.