Urea is one of the most important nitrogenous fertilizers, with the highest nitrogen content of common solid fertilizers. As a stable solid, it is safer and easier to transport than ammonia. In addition to fertilizer, urea is also used increasingly as a very effective additive to diesel fuel for NOx control, increasing the permissible engine operating temperature and thus the overall efficiency of the engine. Other uses of urea include the starting material for melamine production.

Urea synthesis is a two-step reaction, and parts of the process contain significant concentrations of the intermediate material, ammonium carbamate. At the temperature of production (approximately 160°C (320°F) and higher), ammonium carbamate is very corrosive to most materials. Although there are grades of stainless steel that have been specifically designed for use in urea plants, ammonium carbamate’s aggressive corrosiveness limits the maximum temperature and operating parameters that a plant may

maintain.

Zirconium has a very tenacious, naturally occurring, passive oxide layer that is virtually impervious to conditions inside a urea process plant. As compared to stainless steel, zirconium does not require any additional oxygen to be added to the process stream to remain resistant to corrosion. Additionally, zirconium has a much higher temperature capability in the urea process solution compared to other materials. (source ATI materials – Zirconium in Urea Applications)

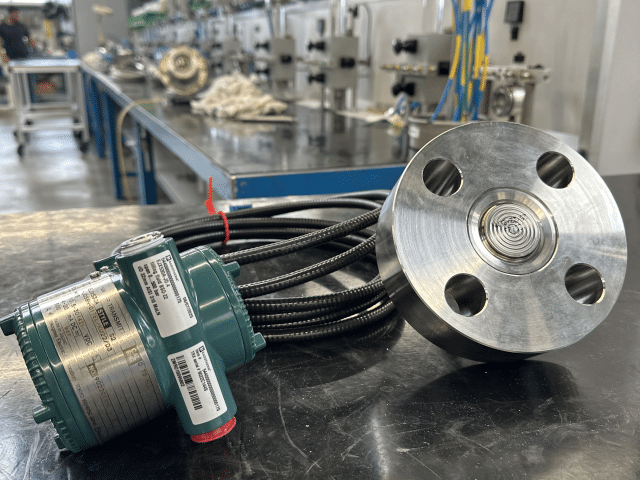

Badotherm has been supplying these zirconium-based diaphragm seal systems to many customers and with huge success. No failures occur due to corrosion and material remains in perfect conditions. Zirconium is also very sustainable, since the body material can be easily re-used and therewith the complete system can be refurbished.

With the industry aiming to increase the turnaround interval times, this material and these systems are perfectly suitable to long time usage. The user cases are incredibly successful.

The easiest solution is with blind flanged BRF seal with zirconium diaphragm sheet. However many designs are extended type seal, where the cover flange is of carbon or stainless steel, but the full body is zirconium, with NO welds in process, other then the diaphragm seal weld, which is of pure zirconium. Often these design are as per licensor specifications such as Casale, Snamprogetti or Stamicarbon. All designs are known by Badotherm and we can manufacture exactly as per these specifications.

More information:

Whitepapers: Whitepapers – Badotherm

blogs: Urea Related blog posts

Datasheet: EXT-FSO-UREA

Datasheet: BRF

Datasheet: BF-FSO