Gold coating for diaphragm seals to protect against hydrogen permeation

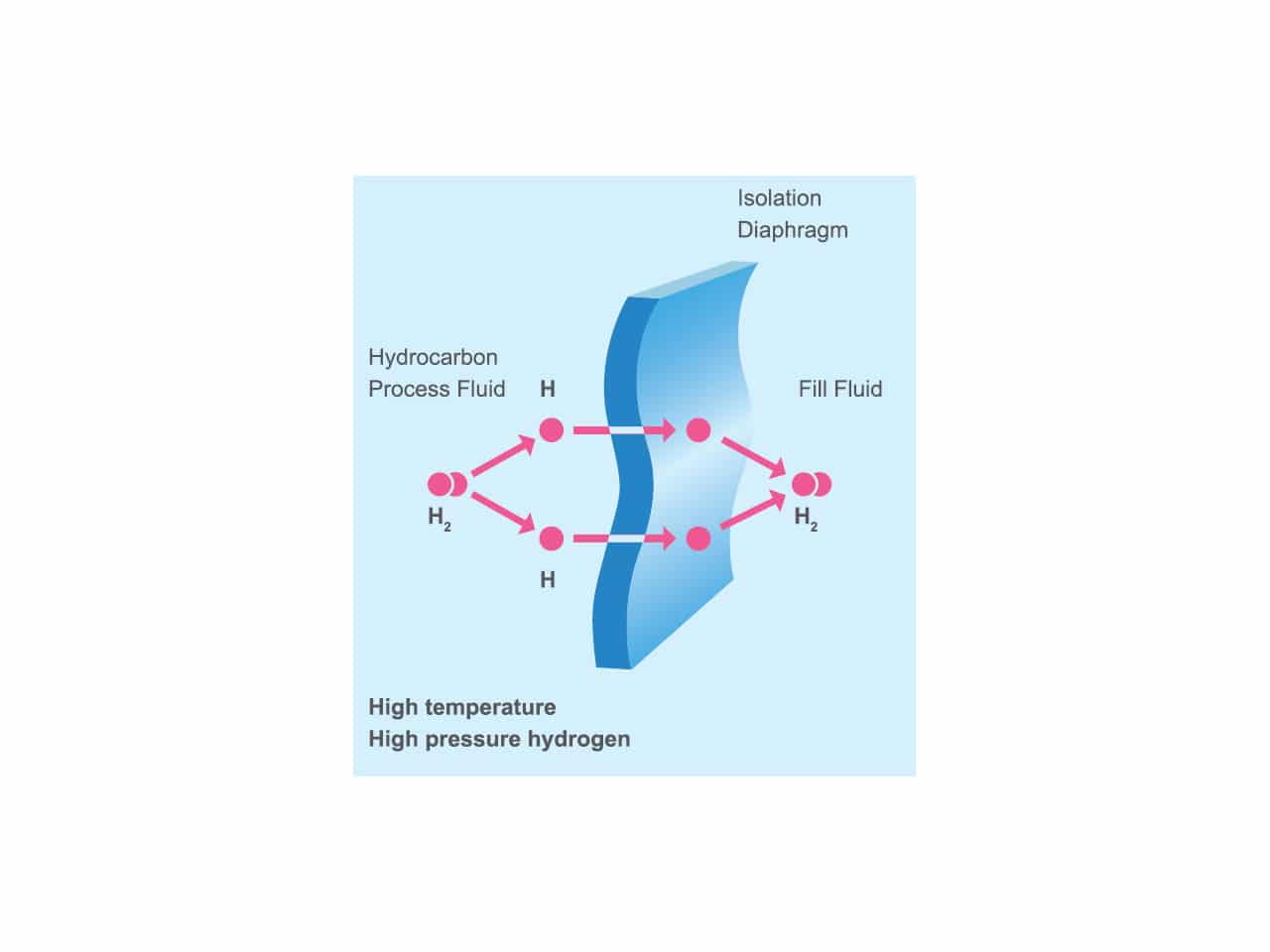

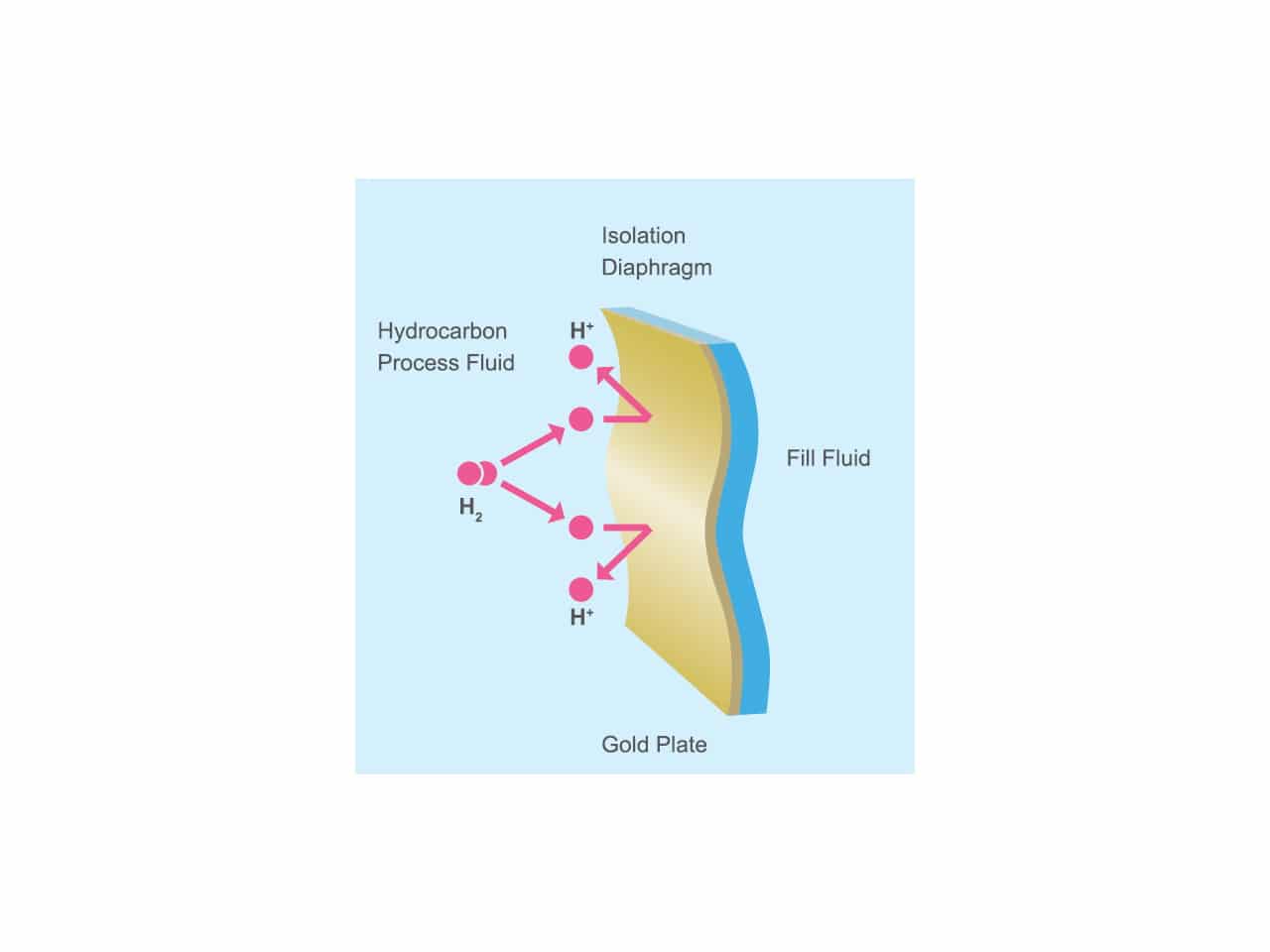

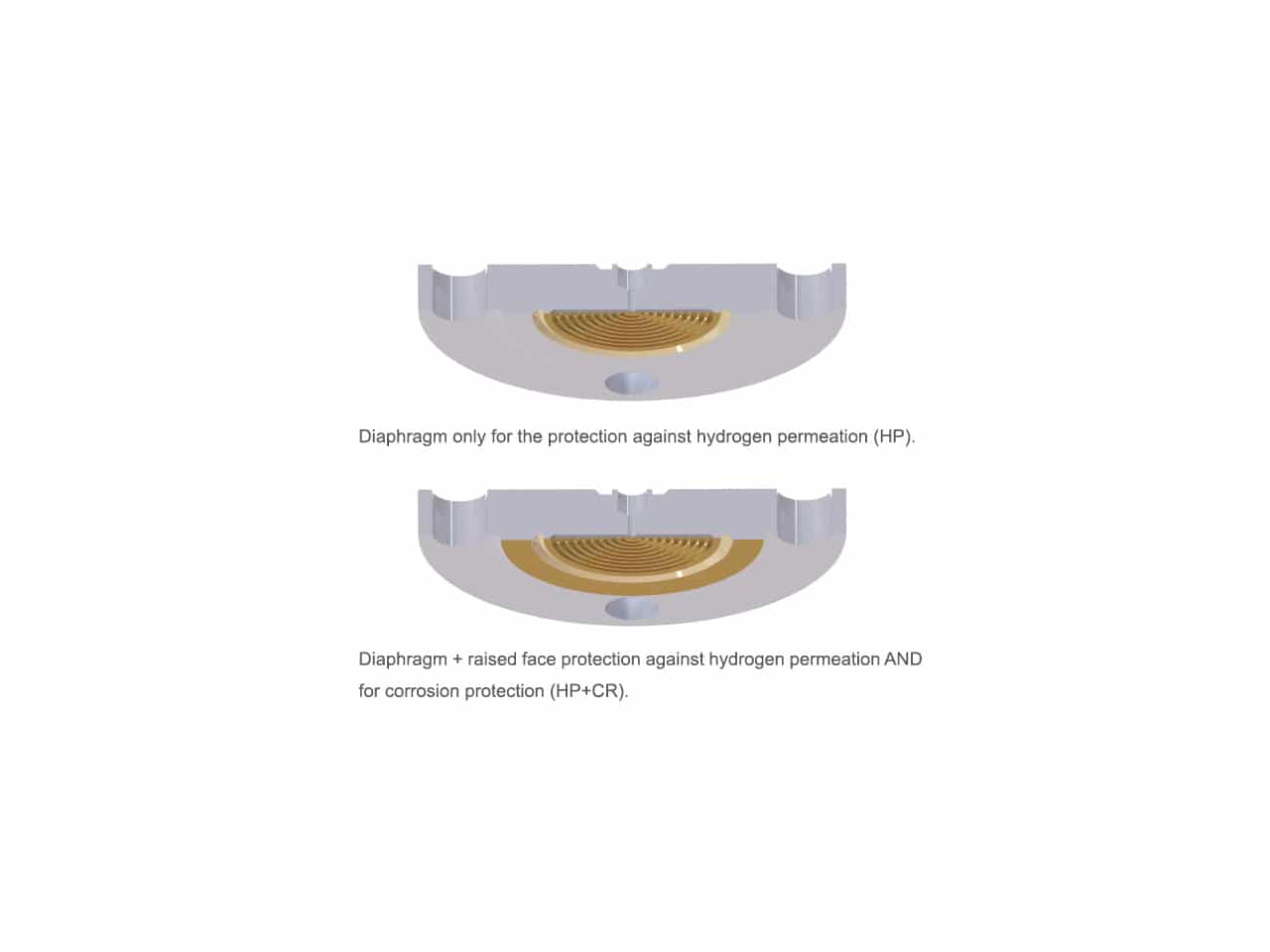

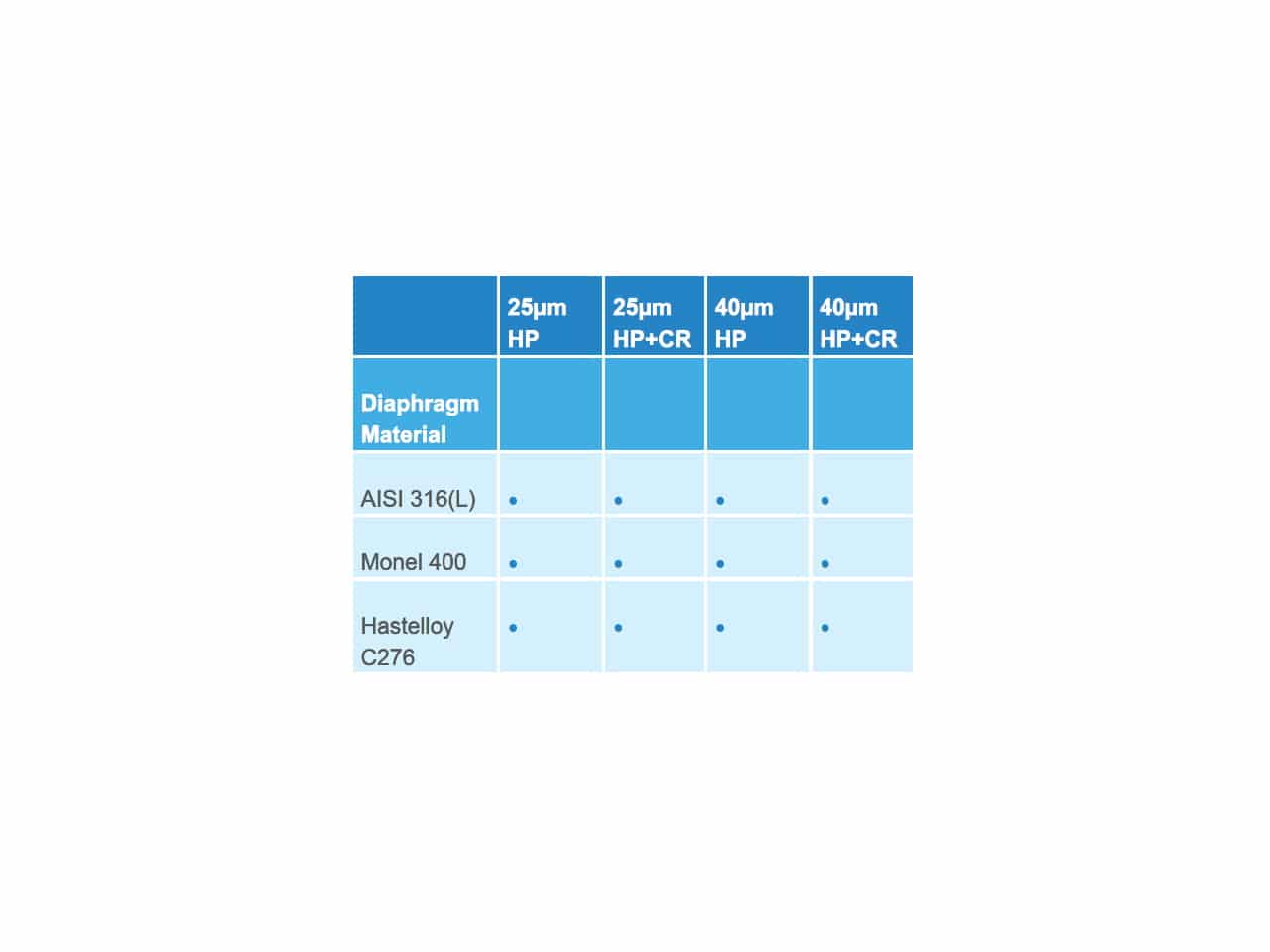

Hydrogen is the lightest and most abundant chemical element. Water, acids, bases, and the related family of organic compounds all contain hydrogen. Although hydrogen is not considered to be corrosive, problems with pressure transmitters mounted with Diaphragm Seals can still occur under specific circumstances. For example, a situation in which either high process pressure, a galvanic reaction or high temperature steam occurs, in combination with high process temperatures, could result in Hydrogen Permeation of the into H+ splitted H² molecules. For this situation, Badotherm offers a solution with the use of a special material on the Diaphragm Seals: a layer of gold coating.