No, the absolute pressure transmitter ranges from 0 mbara. A negative mbara value is not a valid input in pressure transmitters.

BF/BC have the diaphragm weld as a wetted part, this would lead with dissimilar materials to corrosion and/or weld strength problems. BRF/BRC have the diaphragm resistance welded to the body, which result in a weld as a non-wetted part, so allowing to create full wetted parts in exotic materials.

TPE is the square root of the sum of all the effects to the power ²; for diaphragm seals this encompasses: TPE= √((ProcT-Effect²)+(AmbT-Effect²)+(Mtg-Effect²)+(Acc²)+(StatP-Effect²)) (the last Static Pressure Effect obviously only for dP applications)

Accuracy is the uncertainty of the measurement of an instrument under laboratory conditions i.e. @ 20°C ±1°C. Total Probable Error (TPE) is the maximum deviation of the measurement including all effects of process and ambient temperatures and pressures and installation. In the vast majority of the applications the accuracy of the instrument is only a very minor part of the TPE. In this respect it is only sensible to consider the TPE whilst engineering a measurement application.

In order to guarantee corrosion protection, the polymer coatings must have a thickness of ≥ 1 mm. At that thickness the diaphragm flexibility is completely gone and thus no measurement anymore possible. The thickness of the polymer coatings on diaphragm seals varies from 30 – 80 µm. At that thickness the coating only serve as a protection against sticking of the process to the diaphragm.

Having said this, in reality, in some specific situations, it is know that some polymer coating may offer a certain enhanced corrosion protection.

Renowned large international end-users a.o. in petrochemical industries have defined that for regular monitoring and control applications a TPE of 5% is acceptable. There is no standard that defines that

Yes. For gold plating on AISI316L diaphragm in combination with AISI 316(L) flanges the temperature limitation is 430°C. For non AISI 316 constructions such as Alloy C276 or 625 the plating process require a different approach that leaves a risk of adhesion problems. The maximum allowed continuous process temperature is set at 275°C.

The difference between balanced and unbalanced system is the use of equal capillary systems on both sides of the transmitter. It is possible to have a direct mount or wet leg situation in combination with capillary on the other side of the transmitter. The unbalanced system has temperature errors due to the different fill fluid volume at HP & LP side and thus unreliable performance once installed in the filed hence we strongly recommend to use balanced capillary system for reliable measurement. Calculations to see the differences can be done with Basecal perfomance calculation tool.

A full weld construction is a diaphragm seal application where all potential leak point are welded. This includes fill holes, threaded connections, and gasket area’s. Badotherm is specialized in welding special cups on transmitter cells without compromising the functioning and accuracy of the transmitter. The Badotherm design of the full weld construction allows a full repair option when the any failure occur. When repairing the weld cup is removed from the transmitter in order to clean and visual inspect the transmitter cell.

The full weld construction is advised to be used in full vacuum applications, application with big temperature fluctuations, or high pressure applications as these circumstances are known for potential leakage through fitted connections or connections sealed with gaskets. Badotherm full welded construction is repairable and available with almost all transmitter brands.

None. RTJ and RJF are the same however as per ASME B16.5-2020 RJF relates to flanges and RTJ relate to the gasket hence RJF is the correct terminology for flange facing. This terminology is used by Badotherm.

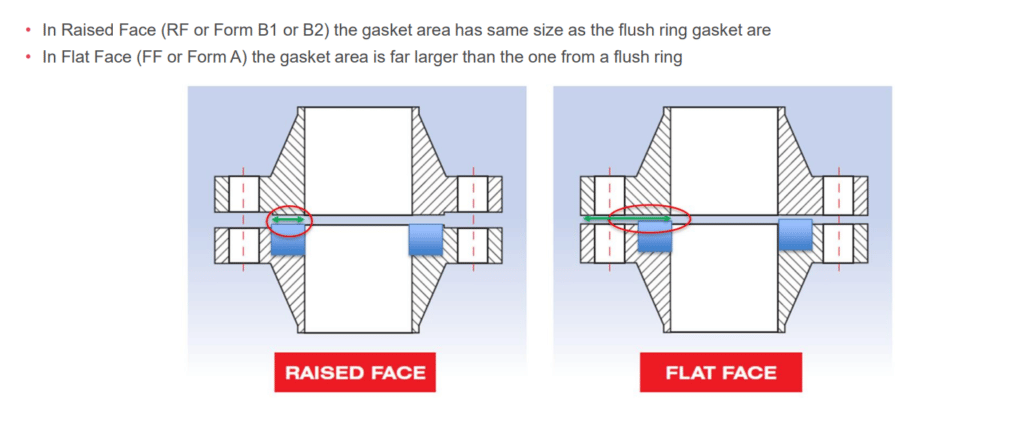

Flat facing is over the full body of the seal and same as the gaskets. The flush ring only covers small portion of the gasket area of the blind flange seal and gasket. So, the principle of FF is not followed anymore. By using a flush ring there is a greater chance of leakage hence we recommend a flush flange (with bolt holes like a blind flange) with FF or Type A facing, instead of a flush ring.

In case of vacuum < the minimum allowed pressure of the pressure transmitters; the transmitter shall be mounted min. 500 mm below the (lowest) diaphragm seal in order to create sufficient static height, to protect the transmitter from irreversible damage

The span in this particular case is 0+4 bar, and that is the span at which we will calibrate the DP transmitter.

The settings of transmitter will be -2+2 bar, however the calibrated span 0+4 bar will be mentioned on the calibration certificate.