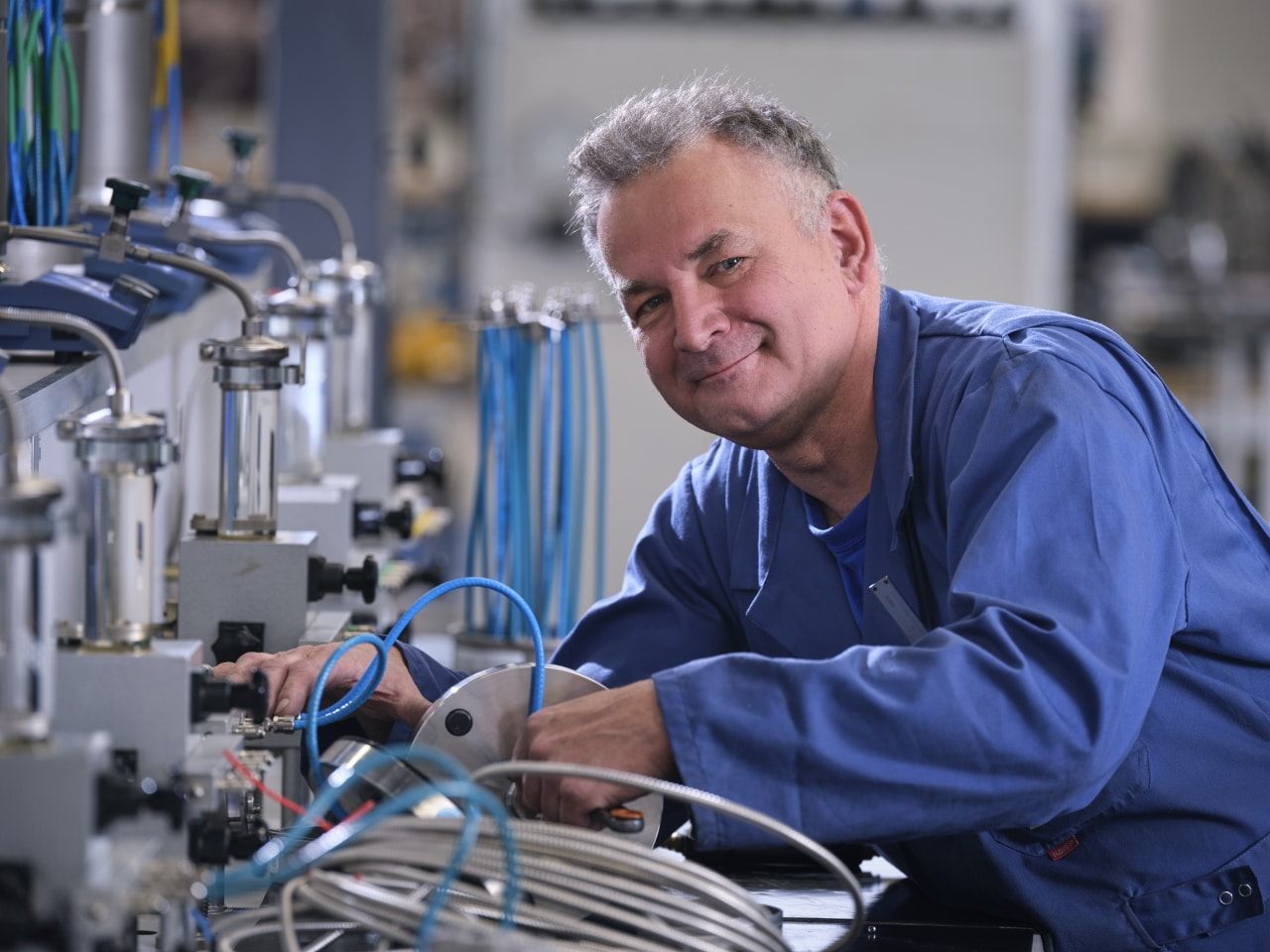

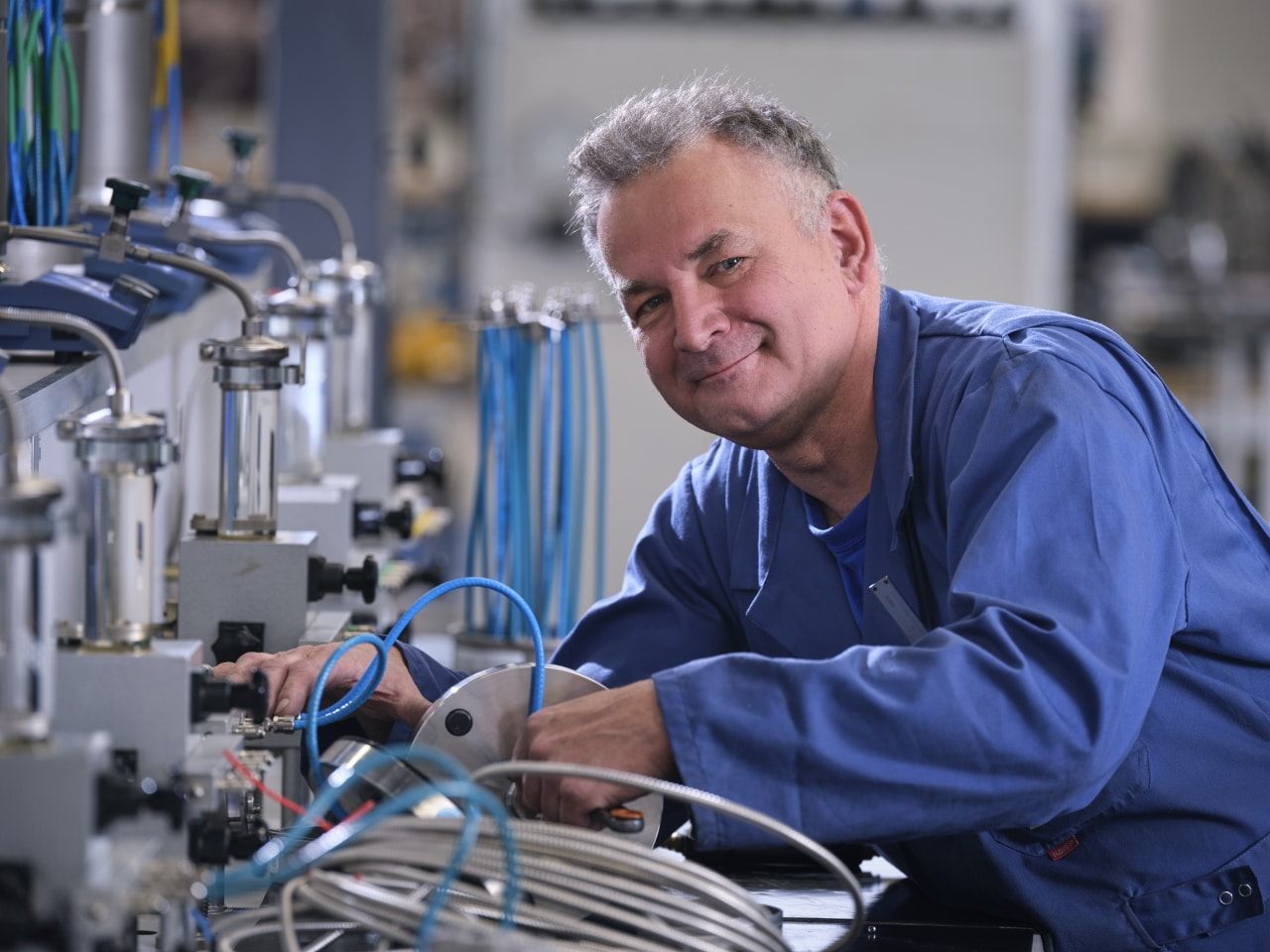

Arjo de Jong

Arjo uses his bike to commute to Badotherm’s factory in Dordrecht, already for 36 years, no matter the weather. He enjoys the brisk mornings that make him start the day fresh.

When we ask Arjo why he choose to work for the same company for more than three decades, he answers confidently, without any doubts; “My work is super diverse. We don’t do the standard assembly line work, where all activities are chopped in small pieces. Our production crew forms a team of all-round experts.” He loves the variety his job offers, no day feels the same as new technical challenges are thrown at him all year round.

Badotherm provides its employees with lots of autonomy to come up with innovative solutions and improvements. “I frequently run tests with different fluids and pressure levels, to push our boundaries and improve the quality of our diaphragm seals even further”.

When you think the company’s innovation focuses only on the products, you’re wrong. With a contagious enthusiasm Arjo continues, “I am currently working on improving some parts of our production tooling (moulds and calibration sets) with the aim to improve factory output and product uniformity. It is really amazing to see how we’ve evolved over the last decades, we have become so much more professional”.

Diaphragm seals that have served their purpose for many years arrive back in the factory to be refurbished by Badotherm’s engineering team. “It is rewarding if you revive a measurement instrument that has been in the field for decades and you can bring it back to a state where it’s simply looking brand new”, Arjo tells with a look that shows conviction. He continues, “We recently got a transmitter back that had worked for 30 years. We replaced the product with the latest generation of our diaphragm seals and put a note in the box wishing our customer all the best for another 30 years!”

The work in the factory is not for the faint-of-heart. “We run our factory as if we’re a professional sports team.

Look at us sitting behind our welding hoods, working on heavy pressure transmitters, assuring every weld is perfect. It’s work that requires a combination of physical stamina and precision!”

Got enthousiastic about Arjo’s story? Check our job openings if there is a position that suits you and come join us.