to extend the threaded process connection the use of threaded nipples can be convenient. Mostly u...

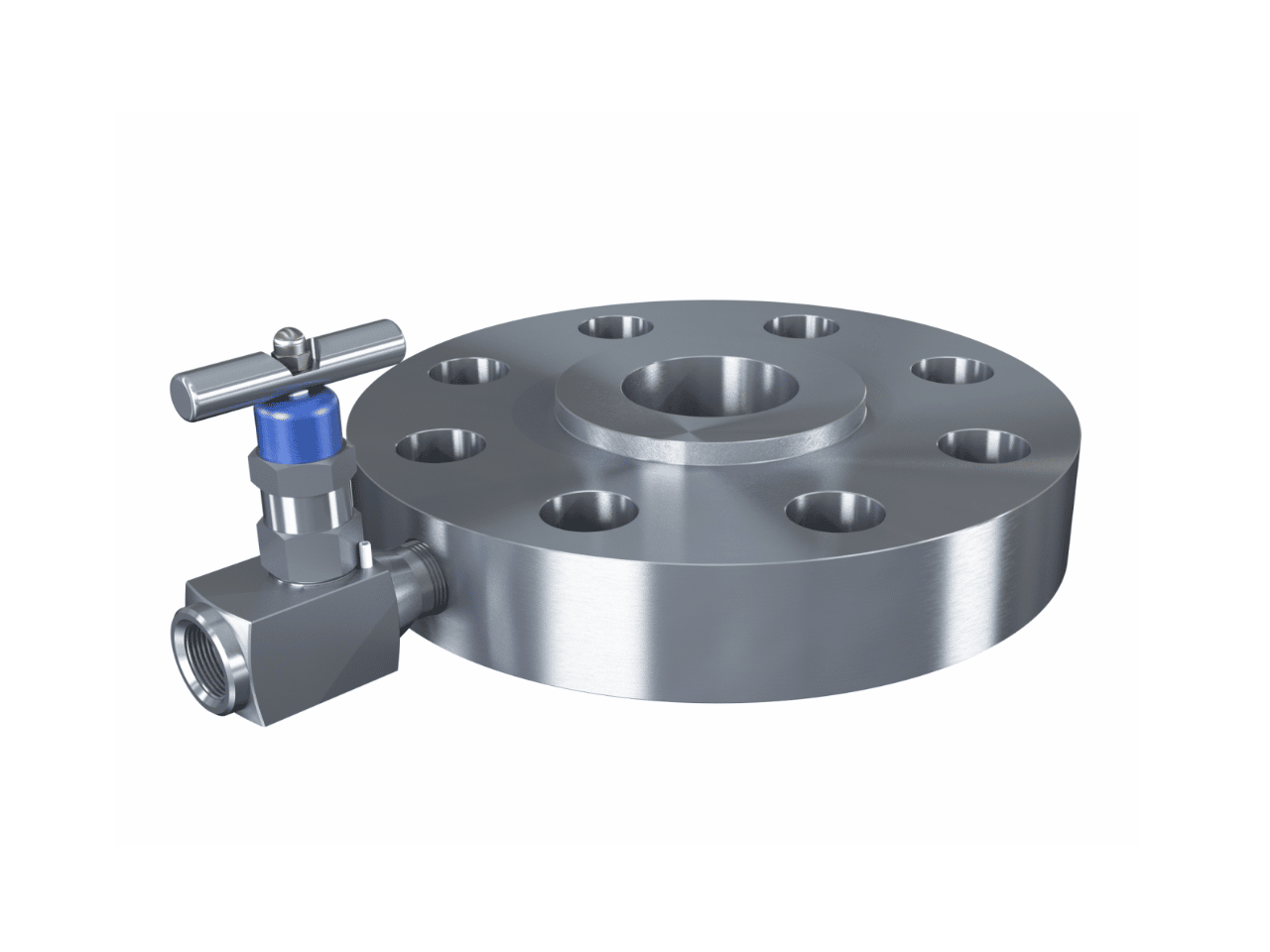

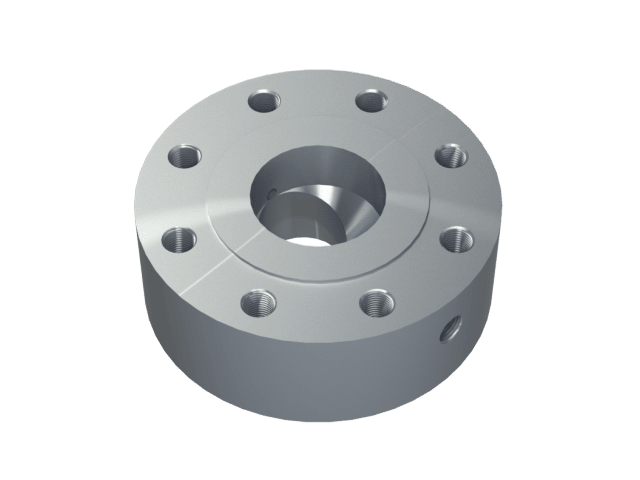

to extend the threaded process connection the use of threaded nipples can be convenient. Mostly used in combination with flush accessories, but can be used to extend pressure gauges from the process line as well. From this point it is possible to build further with needle or ball valves. As these extension nipples are pressurized and wetted parts it is important to make sure the materials are compatible with the process media and the pressure rating. Therefore, a selection of most common materials are listed below with some of the key characteristics.

to extend the threaded process connection the use of threaded nipples can...

to extend the threaded process connection the use of threaded nipples can be convenient. Mostly used in combination with flush accessories, but can be used to extend pressure gauges from the process line as well. From this point it is possible to build further with needle or ball valves. As these extension nipples are pressurized and wetted parts it is important to make sure the materials are compatible with the process media and the pressure rating. Therefore, a selection of most common materials are listed below with some of the key characteristics.