Related products

Capillary lines –Tube, armor and protective sleeve

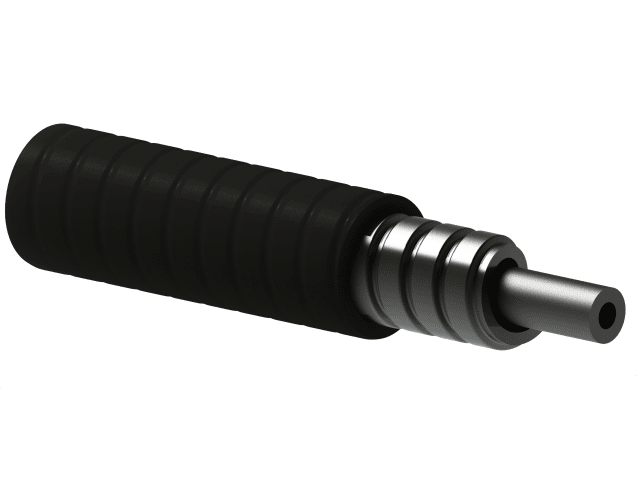

A capillary line is typically used to connect the diaphragm seal remote with the pressure instrum...

A capillary line is typically used to connect the diaphragm seal remote with the pressure instrument. It allows the separation between the measuring instrument, such as a pressure gauge or transmitter, with the process connection. A capillary is typically built up from a tube, an armor and optionally a protective sleeve.

A capillary line is typically used to connect the diaphragm seal remote w...

A capillary line is typically used to connect the diaphragm seal remote with the pressure instrument. It allows the separation between the measuring instrument, such as a pressure gauge or transmitter, with the process connection. A capillary is typically built up from a tube, an armor and optionally a protective sleeve.

Flanged process connection

Not all processes require diaphragm seals, or some process can simply be measured without the use...

Not all processes require diaphragm seals, or some process can simply be measured without the use of a diaphragm seal. For this reason Badotherm offers a broad range of flanged process connectors. This is an adapter product from flange to various instrument connections such as threaded, welded, and to compression fittings

Not all processes require diaphragm seals, or some process can simply be ...

Not all processes require diaphragm seals, or some process can simply be measured without the use of a diaphragm seal. For this reason Badotherm offers a broad range of flanged process connectors. This is an adapter product from flange to various instrument connections such as threaded, welded, and to compression fittings

Extension nipples

to extend the threaded process connection the use of threaded nipples can be convenient. Mostly u...

to extend the threaded process connection the use of threaded nipples can be convenient. Mostly used in combination with flush accessories, but can be used to extend pressure gauges from the process line as well. From this point it is possible to build further with needle or ball valves. As these extension nipples are pressurized and wetted parts it is important to make sure the materials are compatible with the process media and the pressure rating. Therefore, a selection of most common materials are listed below with some of the key characteristics.

to extend the threaded process connection the use of threaded nipples can...

to extend the threaded process connection the use of threaded nipples can be convenient. Mostly used in combination with flush accessories, but can be used to extend pressure gauges from the process line as well. From this point it is possible to build further with needle or ball valves. As these extension nipples are pressurized and wetted parts it is important to make sure the materials are compatible with the process media and the pressure rating. Therefore, a selection of most common materials are listed below with some of the key characteristics.

BDT20 – 100 & 160mm Safety process pressure gauge

Badotherm pressure gauge model BDT20 is the solid front, safety pattern gauge according the highe...

Badotherm pressure gauge model BDT20 is the solid front, safety pattern gauge according the highest class of the EN 837-1 /

9.7.2 and ANSI B 40.1. The BDT20 stainless steel safety gauge has a solid front baffle wall and a pressure relieve back.

Badotherm pressure gauge model BDT20 is the solid front, safety pattern g...

Badotherm pressure gauge model BDT20 is the solid front, safety pattern gauge according the highest class of the EN 837-1 /

9.7.2 and ANSI B 40.1. The BDT20 stainless steel safety gauge has a solid front baffle wall and a pressure relieve back.