DOWNLOAD PDF

Badotherm thermowell model TW2x2 is a bar stock type thermowell with a flanged process connection. The construction is available with straight, stepped, or tapered stem.

DOWNLOAD PDF

Bar stock flanged thermowellBadotherm thermowell model TW2x2 is a bar stock type thermowell with a flanged process connection. The construction is available with straight, stepped, or tapered stem.

DOWNLOAD PDF

Badotherm FSO thermowell model BDTW233 is a bar stock, solid machined type thermowell suitable for a Lap Joint Flange process connection. The construction is available with straight, stepped, or tapered stem.

DOWNLOAD PDF

Bar stock slip-on flange thermowellBadotherm FSO thermowell model BDTW233 is a bar stock, solid machined type thermowell suitable for a Lap Joint Flange process connection. The construction is available with straight, stepped, or tapered stem.

DOWNLOAD PDF

Badotherm thermowell model TW112 is a built-up, fabricated type thermowell with a threaded process connection. The construction is available with straight stem only. Various process connections and instrument connections are available.

DOWNLOAD PDF

Built-up flanged thermowellBadotherm thermowell model TW112 is a built-up, fabricated type thermowell with a threaded process connection. The construction is available with straight stem only. Various process connections and instrument connections are available.

DOWNLOAD PDF

Badotherm thermowell model TW111 is a built-up, fabricated type thermowell with a threaded process connection. Because of its construction the maximum pressure and material selection is limited. The construction is available with straight stem, several process and instrument connections.

DOWNLOAD PDF

Built-up threaded thermowellBadotherm thermowell model TW111 is a built-up, fabricated type thermowell with a threaded process connection. Because of its construction the maximum pressure and material selection is limited. The construction is available with straight stem, several process and instrument connections.

DOWNLOAD PDF

Badotherm thermowell model TW2x1 is a bar stock, solid machined type thermowell with a threaded process connection. The construction is available with straight, stepped, or tapered stem.

DOWNLOAD PDF

Bar stock threaded thermowellBadotherm thermowell model TW2x1 is a bar stock, solid machined type thermowell with a threaded process connection. The construction is available with straight, stepped, or tapered stem.

DOWNLOAD PDF

Socket weld thermowells are designed to be used directly in welding sockets. The BDTW235 is designed in accordance with the ASME PTC 19.3 TW version in three different socket weld sizes.

DOWNLOAD PDF

Bar stock socket weld thermowellSocket weld thermowells are designed to be used directly in welding sockets. The BDTW235 is designed in accordance with the ASME PTC 19.3 TW version in three different socket weld sizes.

DOWNLOAD PDF

Weld-in thermowell is a solid machined thermowell that can be welded in a process line or pipe.

DOWNLOAD PDF

Bar stock weld-in thermowellWeld-in thermowell is a solid machined thermowell that can be welded in a process line or pipe.

DOWNLOAD PDF

Badotherm thermometer model BDTB18 is available in 63 to 160 mm diameter. The BDTB18 is available with various connections, such as: fixed stem on back, bottom, or every angle connection.

DOWNLOAD PDF

BDTB18 – bimetal temperature gaugeBadotherm thermometer model BDTB18 is available in 63 to 160 mm diameter. The BDTB18 is available with various connections, such as: fixed stem on back, bottom, or every angle connection.

DOWNLOAD PDF

Badotherm thermometer model BDTG18 is available in 100/160 mm diameter. The design is made in accordance with the international standard EN 13190. These gas filled thermometers are suitable for corrosive media and environments in chemical process, petroleum, and food industries. The temperature gauge is completely manufactured in stainless steel.

DOWNLOAD PDF

BDTG18 – Gas actuated temperature gaugeBadotherm thermometer model BDTG18 is available in 100/160 mm diameter. The design is made in accordance with the international standard EN 13190. These gas filled thermometers are suitable for corrosive media and environments in chemical process, petroleum, and food industries. The temperature gauge is completely manufactured in stainless steel.

DOWNLOAD PDF

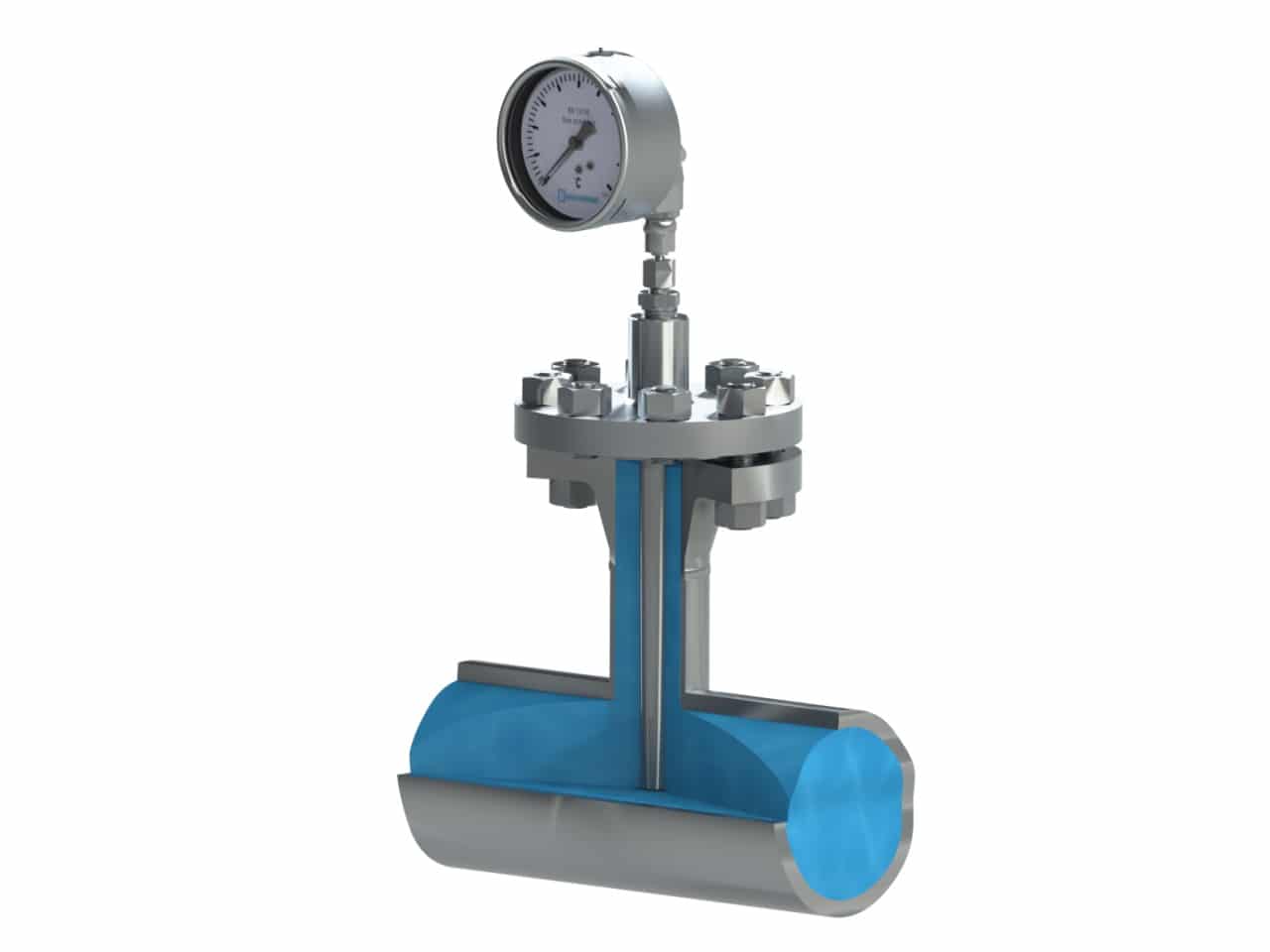

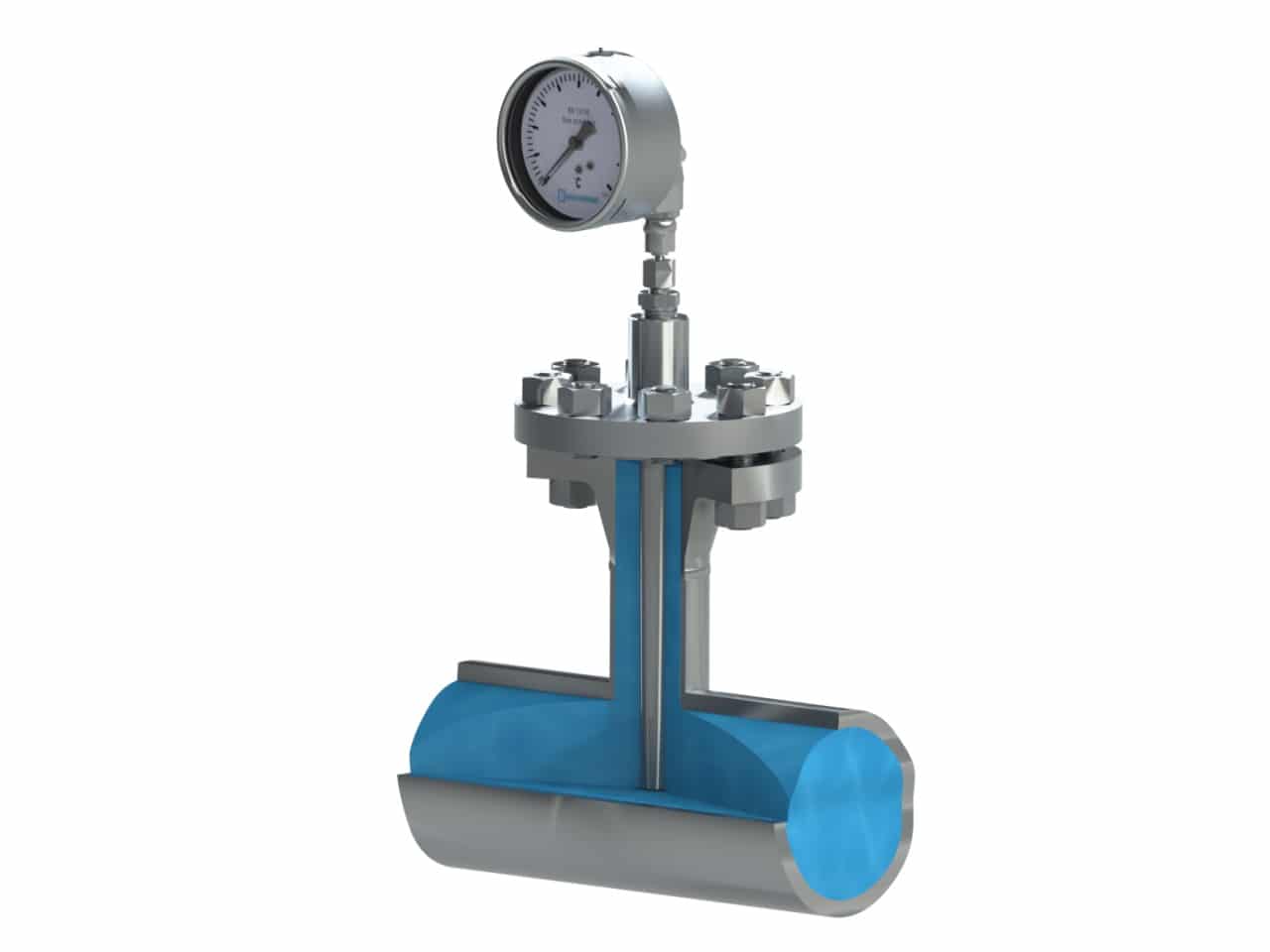

to extend the threaded process connection the use of threaded nipples can be convenient. Mostly used in combination with flush accessories, but can be used to extend pressure gauges from the process line as well. From this point it is possible to build further with needle or ball valves. As these extension nipples are pressurized and wetted parts it is important to make sure the materials are compatible with the process media and the pressure rating. Therefore, a selection of most common materials are listed below with some of the key characteristics.

DOWNLOAD PDF

Extension nipplesto extend the threaded process connection the use of threaded nipples can be convenient. Mostly used in combination with flush accessories, but can be used to extend pressure gauges from the process line as well. From this point it is possible to build further with needle or ball valves. As these extension nipples are pressurized and wetted parts it is important to make sure the materials are compatible with the process media and the pressure rating. Therefore, a selection of most common materials are listed below with some of the key characteristics.