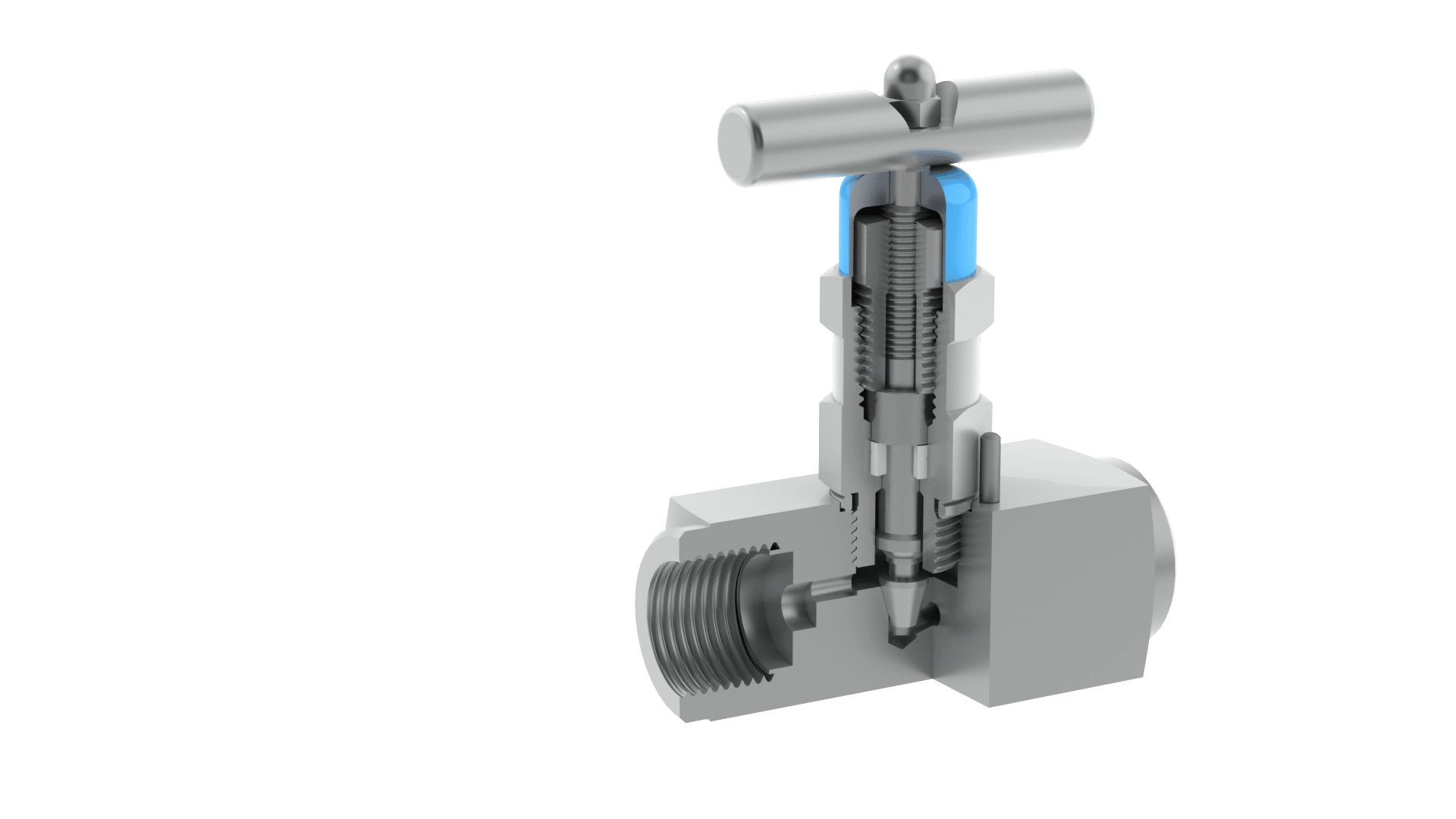

Needle valves

Instrument needle valves are commonly used to shutting off impulse lines and pressure instruments. By using the instrument needle valve series it is possible to remove the pressure instrument without shutting down the process. Another commonly used situation is the mounting of the valves on flush accessories such as drip rings and reducer flanges. This allows that the instrument can be vented during startup or draining during replacement.