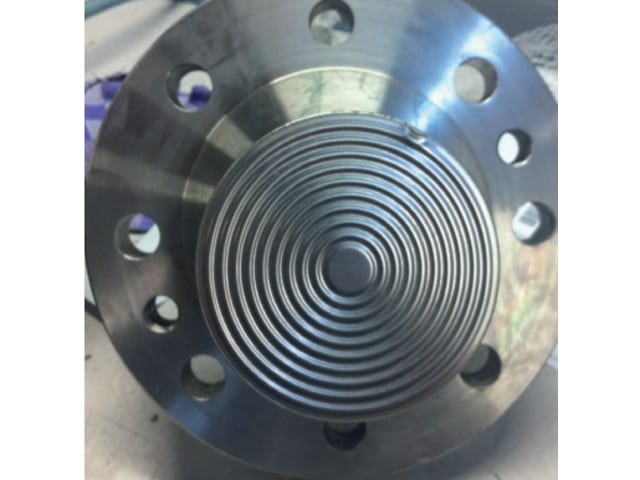

Repair & Refurbishment of Diaphragm Seals

Diaphragm Seals are used to separate the pressure instrument from the process to protect the vulnerable measuring element. This protection enhances the lifetime of the measuring instrument significantly. However, it is possible that the diaphragm eventually breaks. One of the advantages of Diaphragm Seals is that they can be renewed, whilst re-using the pressure instrument. It will function just as a new instrument, but with the benefits of lower costs and a much shorter lead time, compared to buying a new instrument with seals. In addition to short lead times, we also offer rush repairs (within 48 hours) and when requested we analyze the defective instrument to learn what has happened and advice how to improve the reliability and lifetime of the instrument in the future.