Concentrating Solar Power plants (CSP) produce electricity by using mirrors to concentrate sunlight onto receivers, which produce steam to generate electricity. Traditional technologies used in a fossil fuel power plant can be applied to the power block, which utilizes solar thermal energy instead of fossil fuel. Most renewable technologies suffer from a discontinuous energy supply and an unpredictable output due to altering weather conditions and/or energy demands. CSP plants, equipped with a Molten Salts Storage System, store excess heat and stay operational also during evening hours and cloudy days, which significantly increases their electricity output. However, the Molten Salt Parabolic Trough CSP technology, can operate at temperatures up to 550° C by changing only the heat transfer fluid from hot oil to molten salt. A higher steam temperature will achieve higher efficiency in power generation, and at lower costs due to the fact that less volume is required for heat storage. Additionally, molten salt, used as both heat transfer fluid and heat storage medium, will allow for a more simplified plant design as the oil-MS heat exchanger is not required.

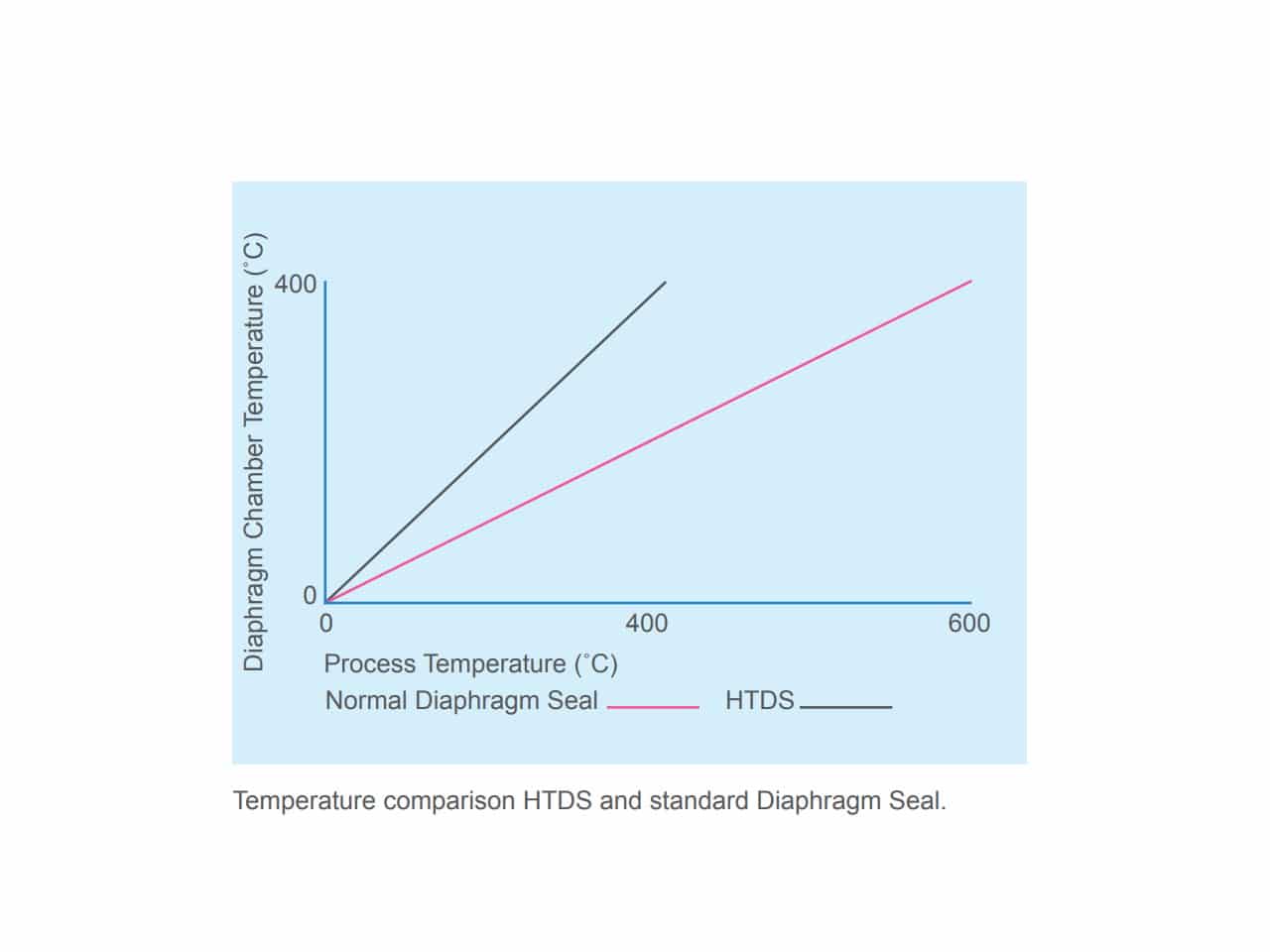

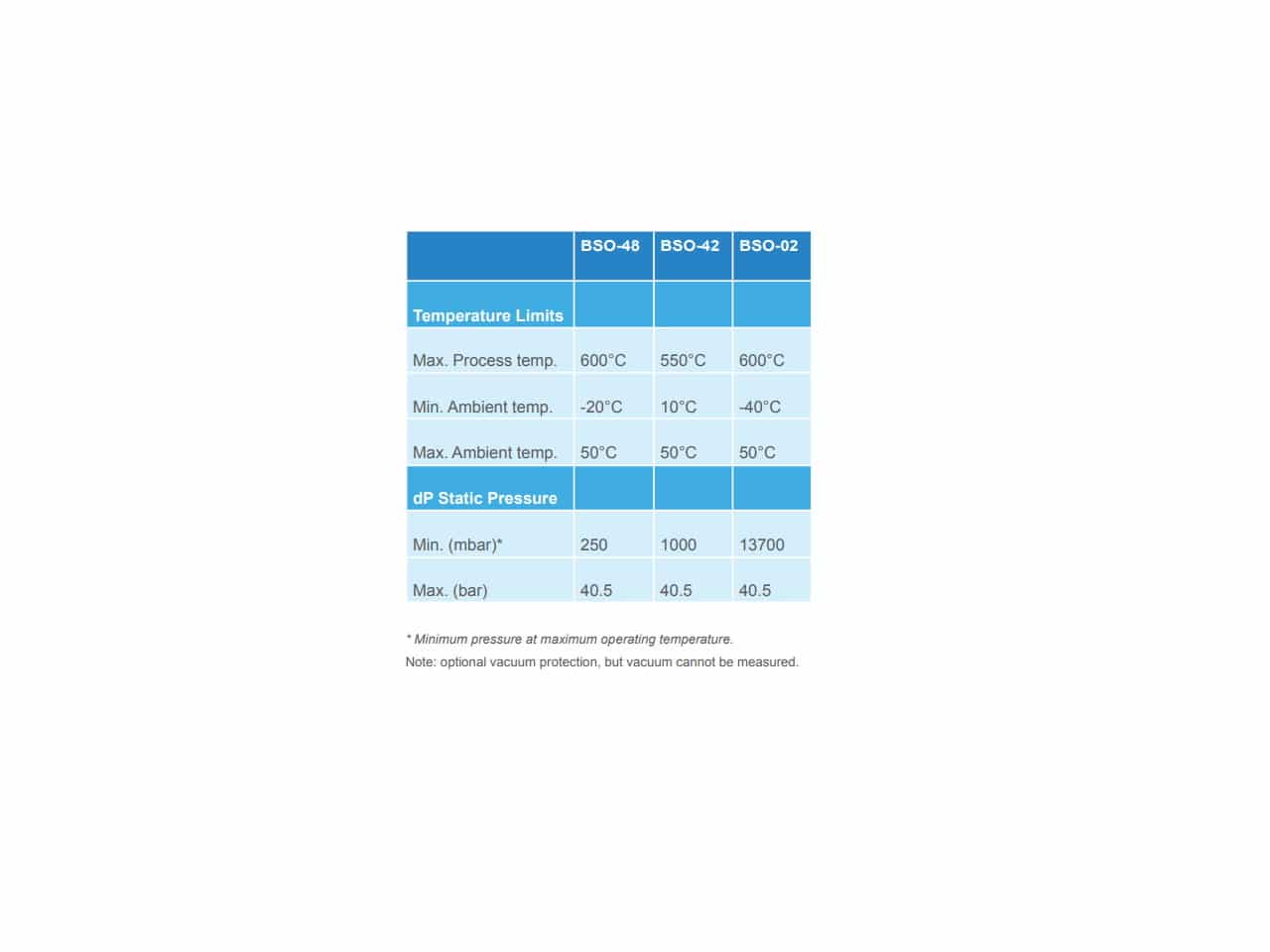

Diaphragm Seal measurements are common in the thermosolar industry. However, for Molten Salt heat storage, the operating temperature was around 550°C. This gave a huge challenge as fill fluids technology did not go above 420°C.

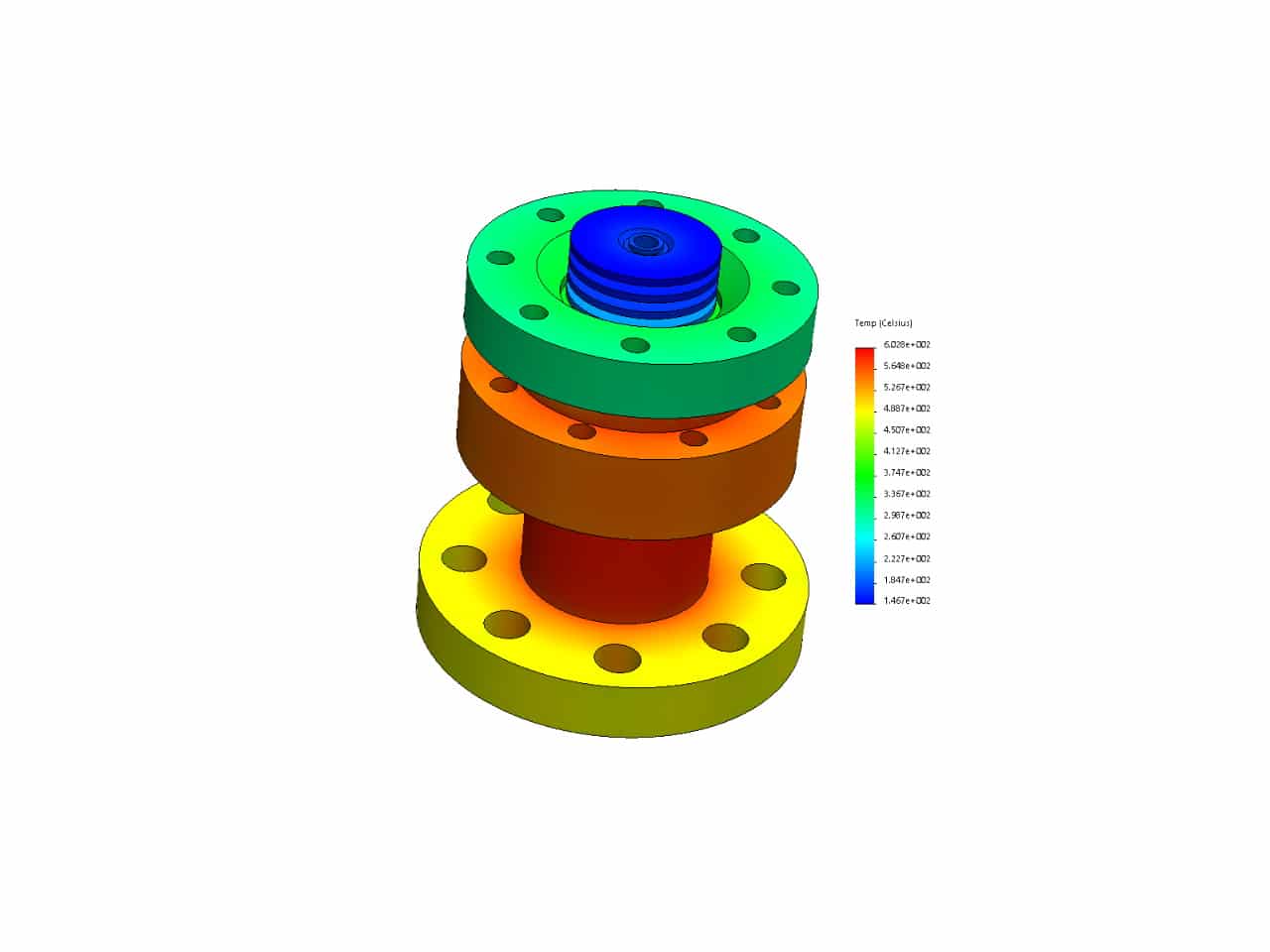

One of the major advantages of the HTDS is that the installation is similar to a standard Diaphragm Seal. The direct mounting on the process, reduces the chance for clogging and give accurate process information. Workarounds such as cooling towers influence the conditions at the sensing element and the final pressure measurement may not reflect as accurate what is going on in the process, as opposed to the HTDS. Still, the cooling tower creates the risk that the process temperature is reaching the diaphragm seal, hence destroying the filling fluid with a maximum limit of 400°C. Cooling towers are also prone to clogging, as the hole is often as small as 3,5 mm. The HTDS also reduces the chance for possible air inclusion, which is more common in the pipe. For Molten Salt applications, the Diaphragm Seal is insulated at a certain temperature to keep the salt molten. Please consult Badotherm for specific insulation recommendations for the HTDS.

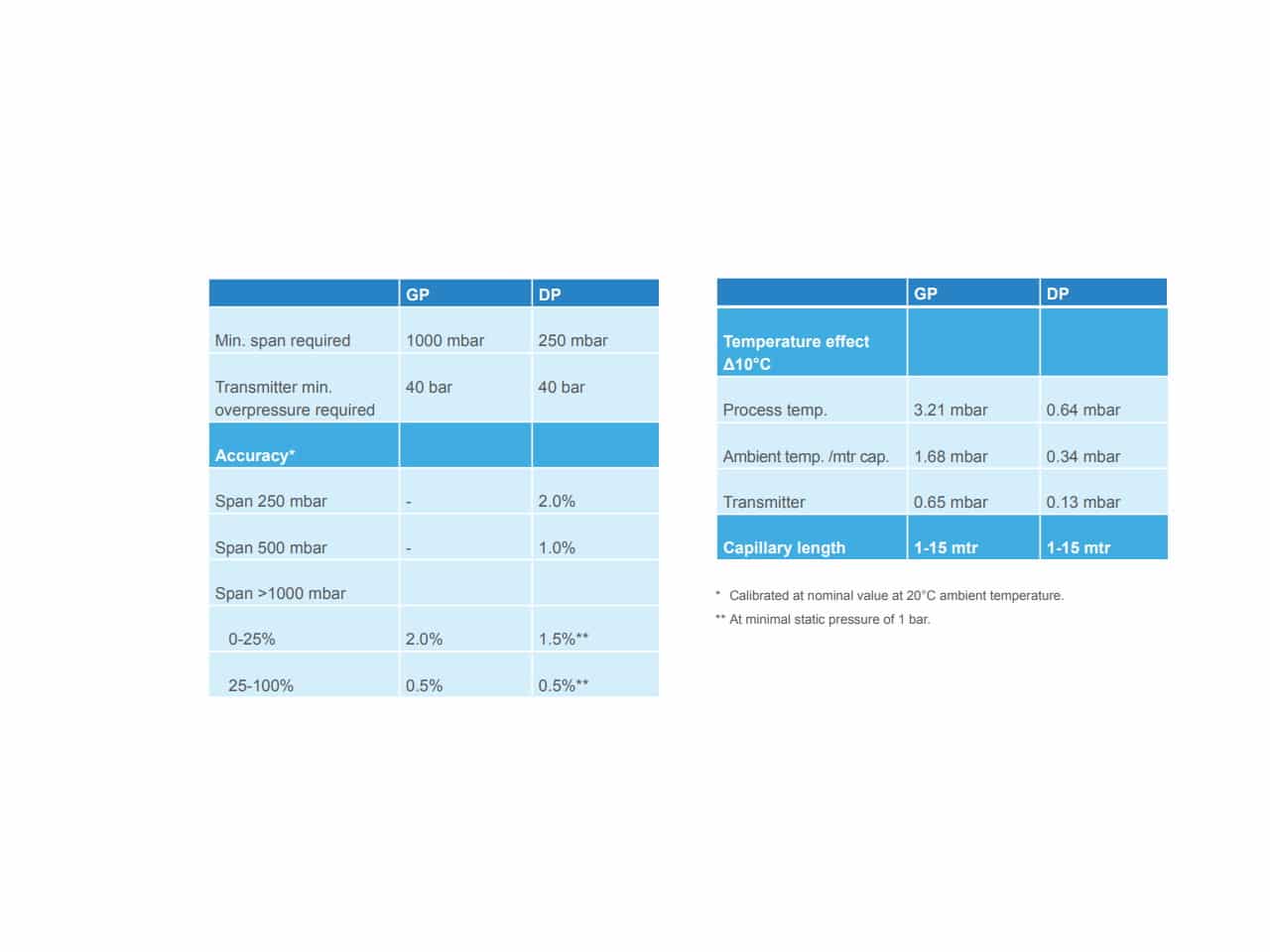

The table presents the accuracy specifications of GP and DP HTDS, as well as the temperature effects, and pressure details.