DOWNLOAD PDF

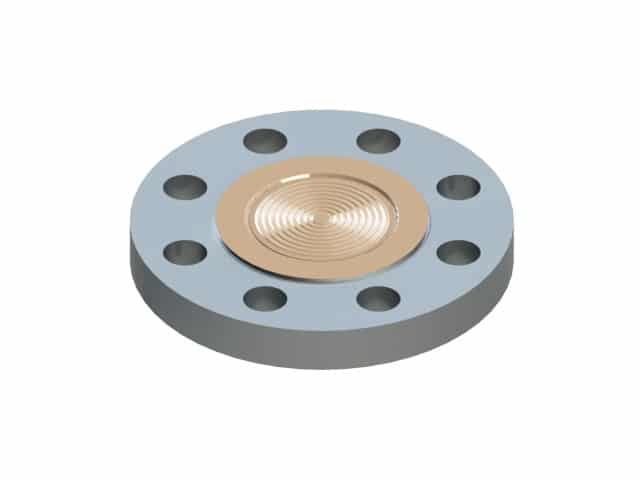

Polytetrafluoroethylene, shortly PTFE, coating has a non-stick function. The standard (S) coating has a thickness of +/- 30µm. Optionally (T) 80µm is possible but will influence the accuracy with low span measurements. For special material applications and for BRF seals a special version is available with a standard thickness. The Low Cure (LC) option takes care of the heat influences caused during the application of the coating.

S

– Thickness: ± 30µm

– Min. temp.: -200°C

– Max. temp: +280°C

– Color: Grey/Black

T

– Thickness: ± 80µm

– Min. temp.: -200°C

– Max. temp: +280°C

– Color: Grey/Black

LC

– Thickness: ± 30µm

– Min. temp.: –200°C

– Max. temp: +280°C

– Color: Grey/Black

DOWNLOAD PDF

PTFE coatingPolytetrafluoroethylene, shortly PTFE, coating has a non-stick function. The standard (S) coating has a thickness of +/- 30µm. Optionally (T) 80µm is possible but will influence the accuracy with low span measurements. For special material applications and for BRF seals a special version is available with a standard thickness. The Low Cure (LC) option takes care of the heat influences caused during the application of the coating.

S

– Thickness: ± 30µm

– Min. temp.: -200°C

– Max. temp: +280°C

– Color: Grey/Black

T

– Thickness: ± 80µm

– Min. temp.: -200°C

– Max. temp: +280°C

– Color: Grey/Black

LC

– Thickness: ± 30µm

– Min. temp.: –200°C

– Max. temp: +280°C

– Color: Grey/Black

DOWNLOAD PDF

Perfluoroalkoxy, shortly PFA coating has predominantly a non-stick function. The corrosion resistance is generally better than PTFE, as its structure is less permeable. Optionally (T) 80µm is available, but this will influence the accuracy. The PFA enhanced (E) version has special fillers to enhance the corrosion resistance.

S

– Thickness: ± 30-40µm

– Min. temp.: -200°C

– Max. temp: +260°C

– Color: black metallic

T

– Thickness: ± 80-100µm

– Min. temp.: -200°C

– Max. temp: +260°C

– Color: black metallic

E

– Thickness: ± 60-80µm

– Min. temp.: -200°C

– Max. temp: +260°C

– Color: red

DOWNLOAD PDF

PFA coatingPerfluoroalkoxy, shortly PFA coating has predominantly a non-stick function. The corrosion resistance is generally better than PTFE, as its structure is less permeable. Optionally (T) 80µm is available, but this will influence the accuracy. The PFA enhanced (E) version has special fillers to enhance the corrosion resistance.

S

– Thickness: ± 30-40µm

– Min. temp.: -200°C

– Max. temp: +260°C

– Color: black metallic

T

– Thickness: ± 80-100µm

– Min. temp.: -200°C

– Max. temp: +260°C

– Color: black metallic

E

– Thickness: ± 60-80µm

– Min. temp.: -200°C

– Max. temp: +260°C

– Color: red

DOWNLOAD PDF

Polyvinylideenfluoride, shortly PVDF, has chemical resistance, but depends on concentration and temperature of the medium.

– Thickness: ± 100µm

– Min. temp.: -55°C

– Max. temp: +120°C

– Color: dark grey

DOWNLOAD PDF

PVDF coatingPolyvinylideenfluoride, shortly PVDF, has chemical resistance, but depends on concentration and temperature of the medium.

– Thickness: ± 100µm

– Min. temp.: -55°C

– Max. temp: +120°C

– Color: dark grey

DOWNLOAD PDF

Ethylene chlorotrifluoroethylene, shortly ECTFE has chemical restance, but depends on concentration and temperature of the medium.

– Thickness: ± 600µm

– Min. temp.: -55°C

– Max. temp: +120°C

– Color: green

DOWNLOAD PDF

ECTFE coatingEthylene chlorotrifluoroethylene, shortly ECTFE has chemical restance, but depends on concentration and temperature of the medium.

– Thickness: ± 600µm

– Min. temp.: -55°C

– Max. temp: +120°C

– Color: green

DOWNLOAD PDF

Fluorinated ethylene propylene, shortly FEP coating has a non-stick function.

– Thickness: ± 30-40µm

– Min. temp.: -200°C

– Max. temp: +205°C

– Color: green

DOWNLOAD PDF

FEP coatingFluorinated ethylene propylene, shortly FEP coating has a non-stick function.

– Thickness: ± 30-40µm

– Min. temp.: -200°C

– Max. temp: +205°C

– Color: green

DOWNLOAD PDF

The virgin PTFE sheet is mostly used at US, USL and USM type of seals as the sheet should be clamped. The sheet is applied together with fluorinated oil to keep the foil in its place in case of disassembly. The sheet is for anti-stick because of the limited thickness of 0.1mm. The foil is in accordance with FDA 21 CFR 177.1550. Virgin PTFE foil cannot be used on vacuum applications.

– Thickness: ± 0.1mm (100µm)

– Min. temp.: -150°C

– Max. temp: +260°C

– Color: white

DOWNLOAD PDF

PTFE sheetThe virgin PTFE sheet is mostly used at US, USL and USM type of seals as the sheet should be clamped. The sheet is applied together with fluorinated oil to keep the foil in its place in case of disassembly. The sheet is for anti-stick because of the limited thickness of 0.1mm. The foil is in accordance with FDA 21 CFR 177.1550. Virgin PTFE foil cannot be used on vacuum applications.

– Thickness: ± 0.1mm (100µm)

– Min. temp.: -150°C

– Max. temp: +260°C

– Color: white

DOWNLOAD PDF

The PTFE fiberglass has a self-adhesive layer that can be used to fix the sheet to the diaphragm. The adhesive is on a silicone basis so cannot be used for oxygen application. The sheet is for anti-stick because of its limited thickness of 0.1mm.

– Thickness: ± 0.1mm (100µm)

– Min. temp.: -180°C

– Max. temp: +260°C

– Color: brown

DOWNLOAD PDF

PTFE adhesive sheetThe PTFE fiberglass has a self-adhesive layer that can be used to fix the sheet to the diaphragm. The adhesive is on a silicone basis so cannot be used for oxygen application. The sheet is for anti-stick because of its limited thickness of 0.1mm.

– Thickness: ± 0.1mm (100µm)

– Min. temp.: -180°C

– Max. temp: +260°C

– Color: brown

DOWNLOAD PDF

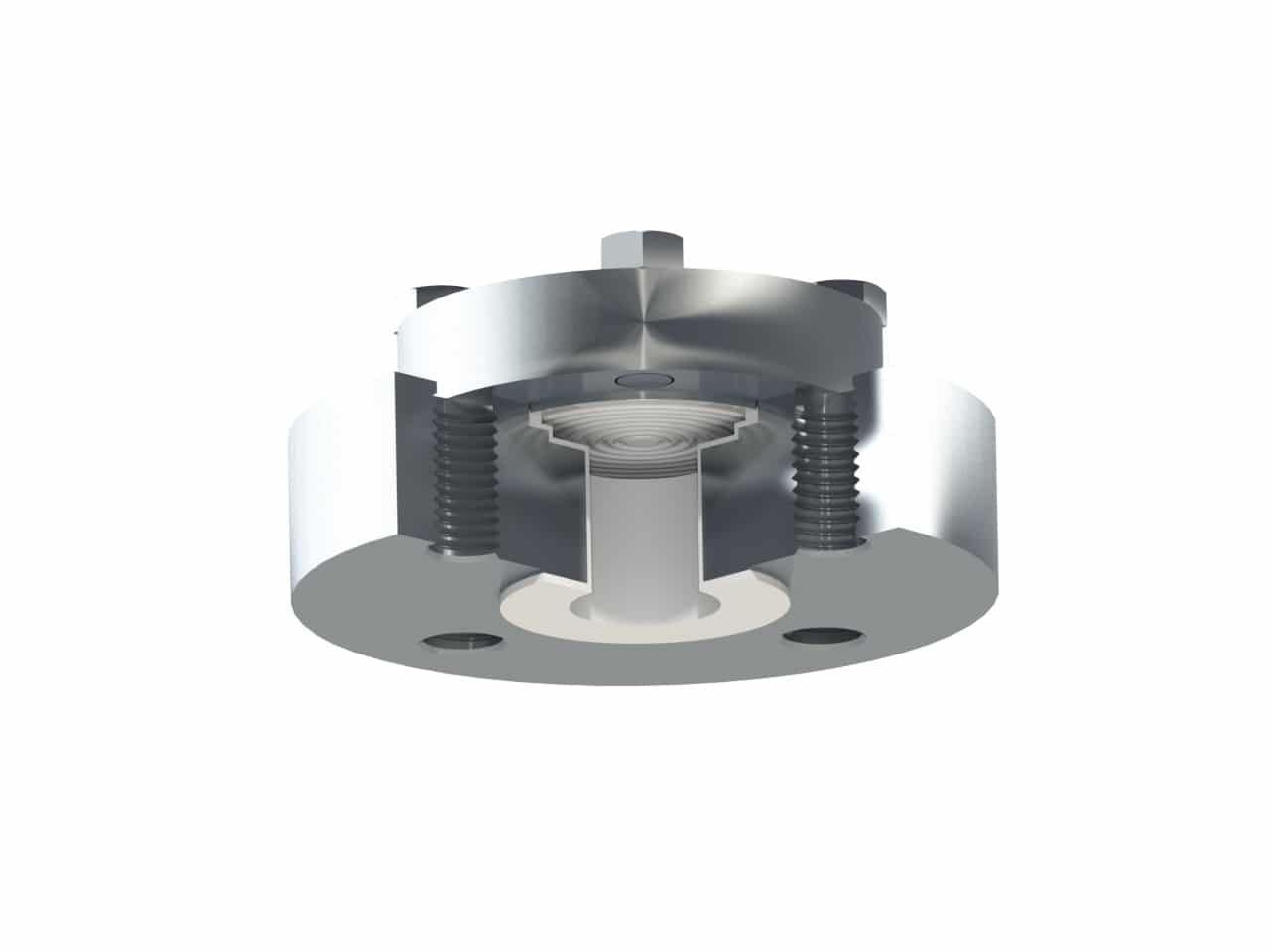

The virgin PTFE lining is a common used protection against aggressive media such as chloride. The lining is a chemical resistant solution because of it’s thickness of 1mm. The lining is shaped into a solid stainless steel part that can be fixed to the process band give the strength up to higher pressure ratings.

– Thickness: 1mm

– Min. temp.: -150°C

– Max. temp: +260°C

– Color: white

DOWNLOAD PDF

PTFE liningThe virgin PTFE lining is a common used protection against aggressive media such as chloride. The lining is a chemical resistant solution because of it’s thickness of 1mm. The lining is shaped into a solid stainless steel part that can be fixed to the process band give the strength up to higher pressure ratings.

– Thickness: 1mm

– Min. temp.: -150°C

– Max. temp: +260°C

– Color: white