In general, polymer material are fully chemical resistant as from a thickness of 1mm. This thickness is not possible on the diaphragm, as it will lose all its flexibility and sensitive. For coatings there are several thicknesses possible as from 40 micron up to 60-80 micron for PTFE and PFA or even 600 micron for ECTFE. Depending on the chemical process the coating might be more or less chemical resistant. Often it is a search for the best combination of non-stick purposes, chemical resistance, wear resistance and temperature limitations.

PFA-Enhanced

Perfluoroalkoxy, shortly PFA coating has predominantly a non-stick function. The corrosion resistance is generally better than PTFE, as its structure is less permeable. Especially for additional chemical resistance there is a special version. This is called PFA-enhanced (E), which has special additives (fillers) to enhance the corrosion resistance. This is a 60-80 micron thick coating layer, with a maximum operating temperature of 260°C.

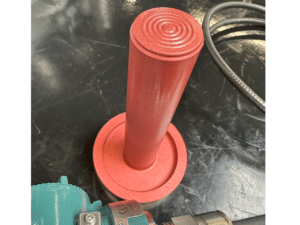

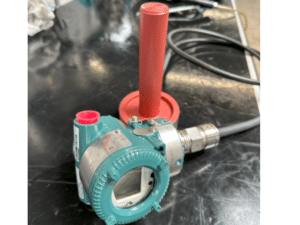

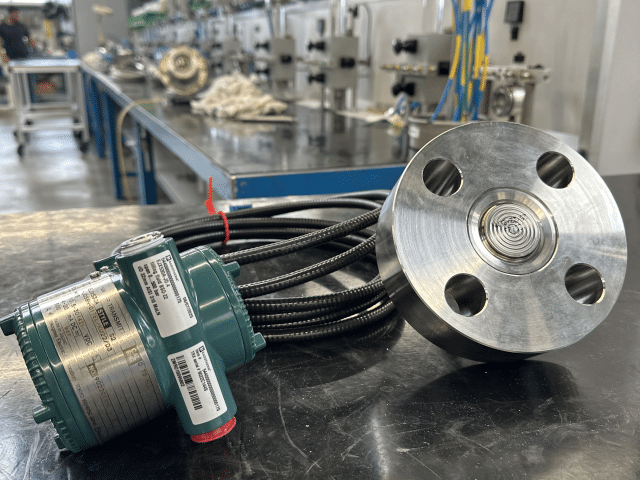

We give this coating a red color as you can see on the images.

This coating can be executed on many type of diaphragm seals. See these example below, where it is executed on an and the PFA enhanced coating. The instrument is equipped with a special Fomblin blend filling fluid as per customer requirement.

@Yokogawa EJA530E

1.5 meters of capillary with stainless steel armor and black PVC sleeve

EXT-BC in full alloy C276 body material

size 2″ 300-2500# LTF

150x32mm

If this special enhanced version is good for your process is difficult to predict. We only know several cases were customer based on trial and error where this coating has shown very good results. Its uptime extended 6x compared to the standard coating in this specific case.

More information:

Website: High End Materials – Polymer coatings

Datasheet:Polymer Solutions

Blog: Protect your instruments with polymer coatings

Blog: Corrosion protection: PTFE lining and polymer coating with C276 alloy diaphragm