A urea plant (identity confidential) has installed in a high pressure and high temperature carbamate gas line a BADOTHERM EXT Full Zirconium diaphragm seal pressure measurement. The material of construction of the pipeline is duplex 2205, the pipeline is electrically traced and operates at 150 bar and 190oC. The nozzle for the pressure measurement is located in the top of a horizontal part of the pipeline. One can state these are really extreme process conditions, with typically heavy corrosion problems due to ammonium carbamate.

Other similar applications are:

– Measure the Synthesis Pressure in the high pressure carbamate gas line close to the safety valve in any urea plant

– Measure the Synthesis Pressure at any other location in the synthesis section of any urea plant like ammonia feed, CO2 feed, air supply, etc.

– Measure the Liquid Level in the High Pressure Scrubber of a STAMICARBON urea plant.

– Now it becomes attractive to check the feasibility to measure also other liquid level applications like the high pressure separator in a SAIPEM urea plant.

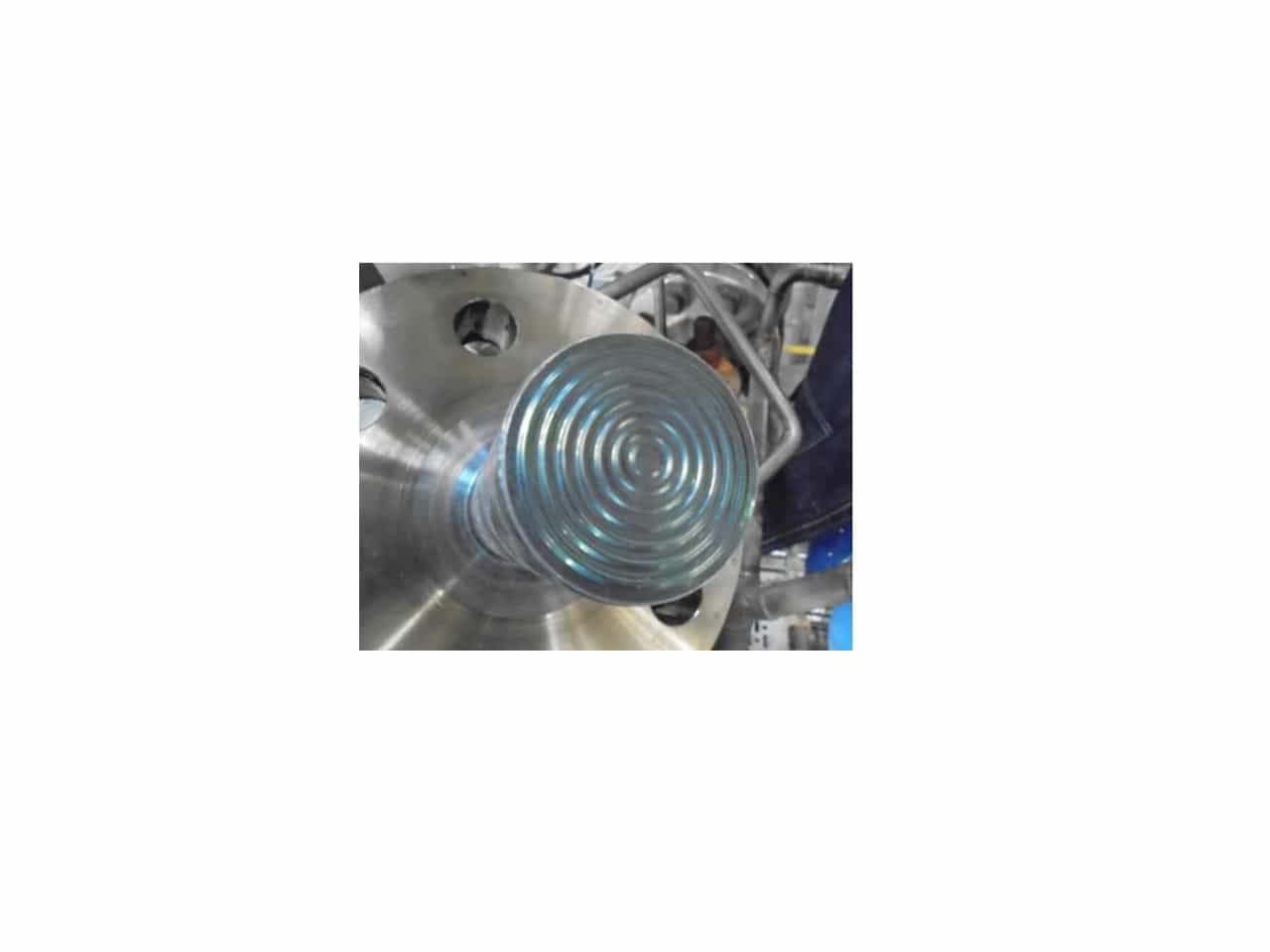

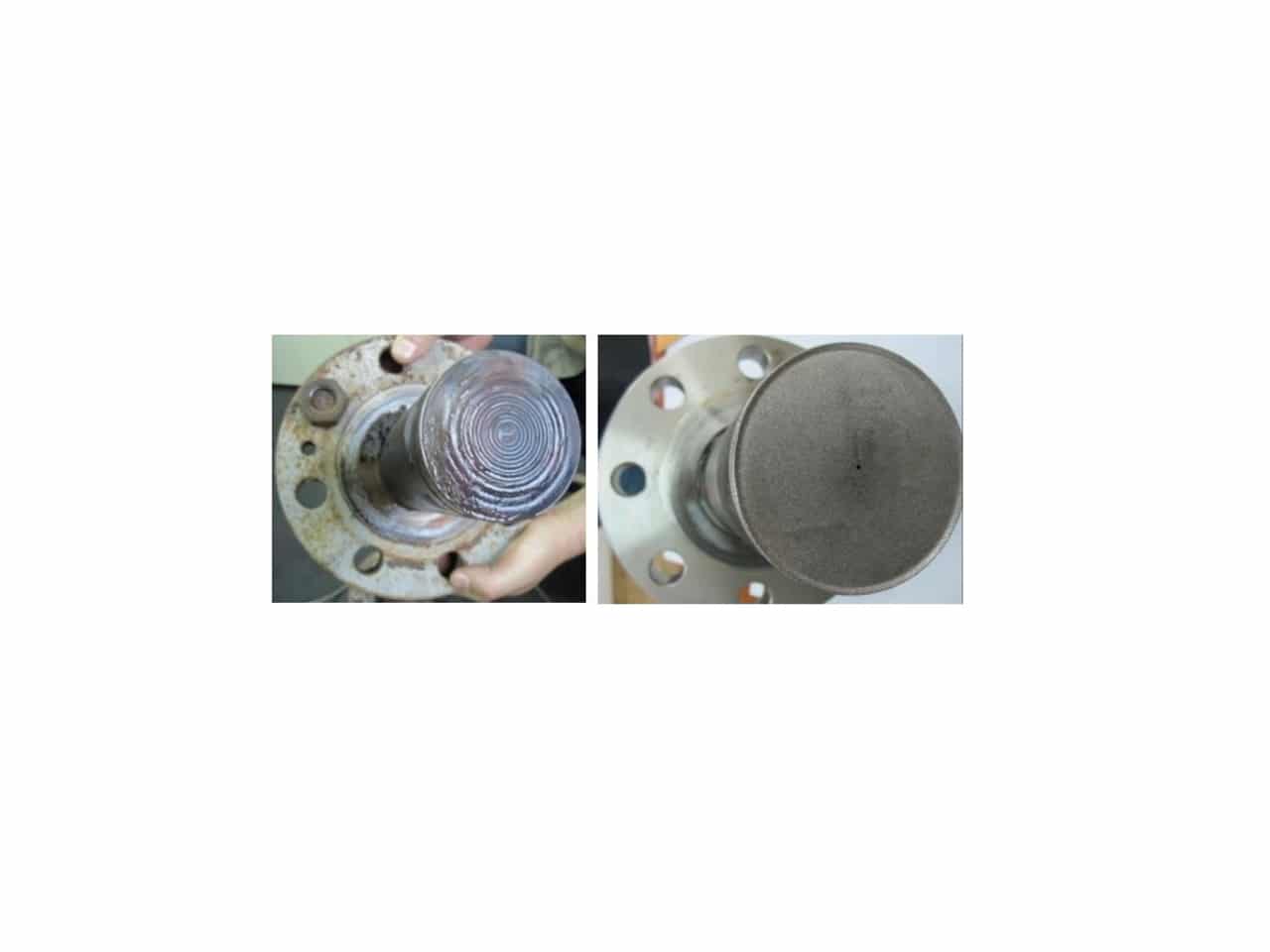

Measuring pressures, levels and delta-P’s in UREA plants is a real challenge. Crystallization, erosion and corrosion risks have to be taken care of. Typically diaphragm (or membrane) type of measurements are

applied nowadays but its lifetime is typically limited (e.g. max one year). After this period, these diaphragms face corrosion problems and mostly needs to be replaced. This means the UREA plant needs to shut down mostly unexpected leading to significant costs in production loss.

More and more UREA plants target continuous running periods between planned turnarounds of two, four to even six years. Sometimes one is able to keep the plant in operation but one needs to operate the plant under non optimum process conditions. Such a situation also leads to a significant negative financial impact as illustrated in this paper. BADOTHERM is a well-known manufacturer of reliable diaphragm seal type pressure, level and delta-P measurements suitable for all UREA process technologies.

Significant costs can be avoided and additional profits can be gained with the BADOTHERM Diaphragm Seals mounted to Pressure Transmitters, for pressure, level or delta-P measurements. Badotherm has several designs and materials available meeting the specific requirements of the UREA industry.

Everyone managing a part of a production plant in the petro-chemical industry wants to maintain a continuous and high output, safely and efficiently. However, (un)scheduled downtime due to pressure measurement failure or unreliable or failing measurements seems unpreventable and are cumbersome to fix, especially with pressure being the most measured entity.

To what extent those issues slow your processes down and consume your valuable time depend heavily on who you select to be your service provider. It is our strong conviction that the number one factor is accessibility. Because effective communication between you and your supplier results in the right engineering and failure could become a problem of the past.

We’ll tell you more about the importance of accessibility in this whitepaper.

Yara International is one of the leading fertilizer production companies worldwide. As part of Yara’s sustainability ambitions to reduce its own emissions and improve productivity at its production sites, operational excellence and continuous process improvement is key. All with the aim of improving reliability at plants and optimizing end-to-end business processes.